CNC Polishing Machine

4 spindles and 6 axes link CNC polishing machine, dynamic polishing machine, cloth wheel forward and backward and spindle rising and falling, cloth wheel automatic compensation and linear speed compensation; It can freely set the waxing time and CNC frequency.

GetThis article is also available in the following languages:

English

Tiếng Việt

CNC Polishing Machine

Product Specifications

| Attributes | Parameters |

|---|---|

| Product Name | CNC Buffing Machines, CNC Polishing Machines |

| Product Brand | Xiangying Machinery |

| Product Specification | CNC Polishing machines with 4 spindles and 6 axises |

| Product Type | NC polishing machines |

| Operational parameters | CNC programming |

| Product Material | Steel, Steel plate |

Applicable Industries

4 spindles and 6 axes link CNC polishing machine, dynamic polishing machine, cloth wheel forward and backward and spindle rising and falling, cloth wheel automatic compensation and linear speed compensation; It can freely set the waxing time and CNC frequency.

The Control system adopts advanced technology and controls 6 axes at the same time; It has low vibration of polishing head and high control accuracy and is suitable for a small number of diverse products polishing.

Adopted Servo System (High Operating Efficiency, One KeyCompletion), it can quickly replace fixtures and save power (less than 11KW).

Automatic grinding can be reduced labor costs and improved production efficiency, suitable for batch operation.

Easy to observe and operate by the fully enclosed shield,

Can be equipped with dust collector in line with environmental requirements.

Specially designed for the polishing of a great variety of sanitary wares, hardware, and electronics with complicated and irregular shapes

Applicable Industries

Hardware Industry

Lock Industry

Bathroom Industry

Our Company

MAKERAZE, Located in the high-tech industrial zone of Jiangmen, Guangdong Province, China. We have the professional production technology of buffing and polishing materials in the surface finishing industry for about 100 years.

The industry which we serve is included in Automotive Aluminum Wheels、Door Hardware、Cutlery、Automotive Dashboard、Plumbing Fixtures、Cookware、Lighting、Fireplace Hardware、Medical and Dental、Printed Circuit Boards、Cell Phone Case、Lock Hardware、Musical Instruments、Furniture、Jewelry、Medical equipment…

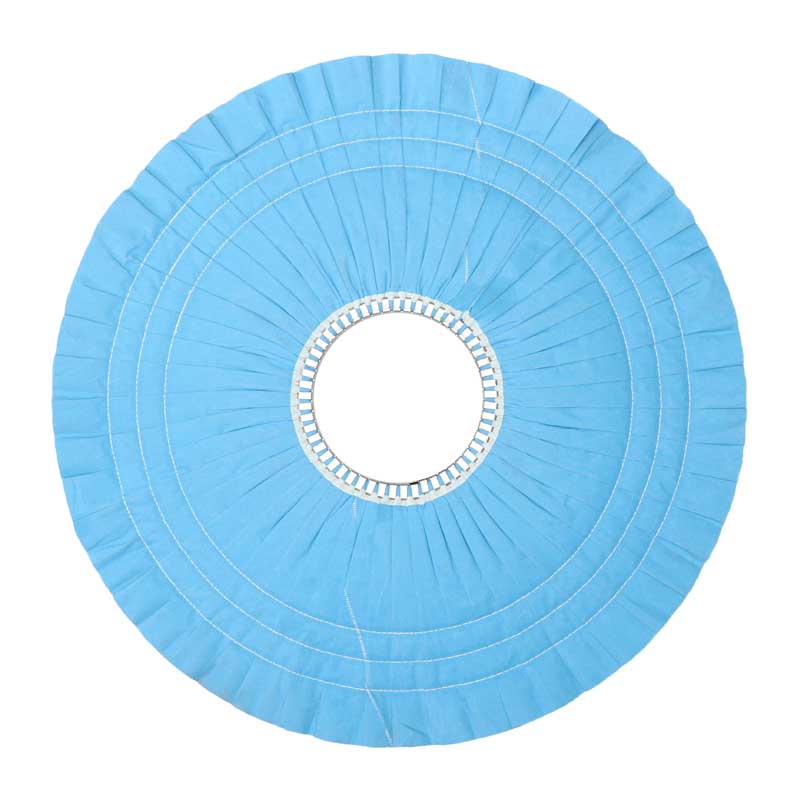

The products which we supply are including Buffing Bar Compounds、Buffing Liquid Compounds and Spray Gun System、Cloth Buffs、Sisal Buffs、Pressure Tanks、 Buffing Equipment、Grinding Materials、Specialty Abrasives、Non-woven and Coated Abrasive Rolls、Flap Disk、Flap Wheels、Belts and Convolute Wheels、Fuel additives、Buffing Raw Materials、Polishing Materials.

We have a raw material laboratory with R&D ability to give us the well-skilled to adjust the formula of buffing compounds. Regarding the finished products, which are tested by a robotic cell in our appliance laboratory, give us the highest performance by simulated and alternative testing, meanwhile, it gives the best production benefits to the customers. We also support OEM which is required by various brands. And sincerely welcome to have any joint of cooperation and any inquiry.