This article is also available in the following languages:

繁體中文

The car engine is the top priority of the automobile and the heart of the automobile, which plays a decisive role in its power, economy, stability and environmental protection. Car engines have a variety of bent pipes that need to be polished to ensure their performance.

As this is to polish the inside of the pipe, the usual grinding method is not applicable. This article will explain how to polish a bent pipe inside a car engine.

Polishing method

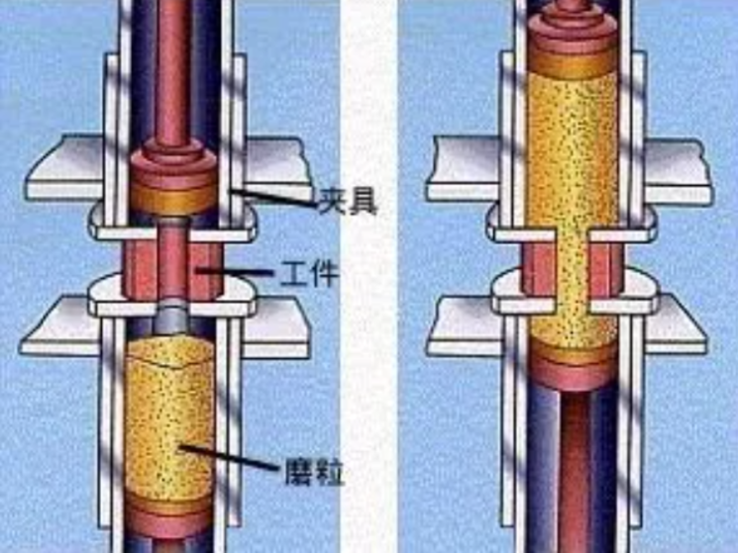

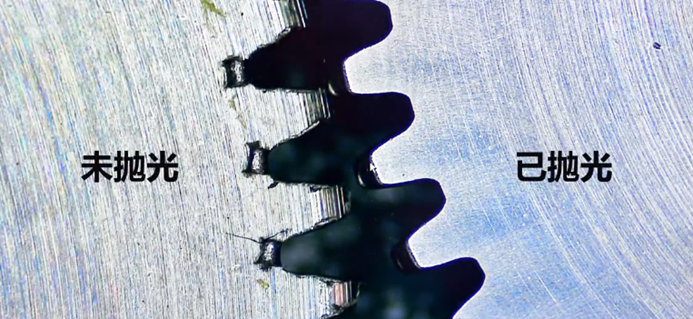

Abrasive flow machining is also known as fluid processing. Its working principle is to fix the workpiece that needs to be processed on the machine tool, extrude semi-solid or liquid abrasive to the inside of the pipeline, and grind back and forth in the circle to remove the burrs inside the pipeline.

The abrasive roughness ranges from tens to thousands of mesh, which is sufficient to cope with the different roughness and materials of the workpiece, and complete the fine treatment.

According to relevant statistics, the use of abrasive flow machining after the engine of an automobile has resulted in a 7% reduction in exhaust emissions, a 6% increase in engine power and a 5% increase in mileage. This method is used in some luxury sports cars, especially race cars.

Due to the fluid nature of the grinding medium, abrasive flow resolves different types of hole-in-wall polishing, such as special shaped holes, curved holes, micro-pores, and porous artifacts.

Therefore, in addition to automobile cylinders, other automobile components such as fuel nozzles, turbine housing and blades, gears, brakes, and some aviation components can also be machined using abrasive flow processes.