This article is also available in the following languages:

繁體中文

1.Reduce operational hazards and increase work efficiency.

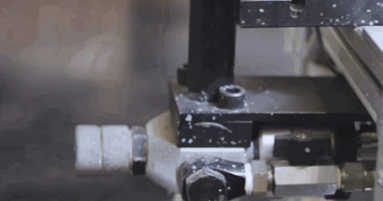

The polisher eliminates the need to interrupt the polishing work and contact with the rotating polishing wheel, and automatically controls the spraying of the polishing paste while avoiding operational hazards, saving 25 percent of operating time and improving work efficiency.

Save time on wheel replacement, as the cooling effect of the liquid polishing slurry increases the life of the wheel, so the amount of wheel replacement is reduced and the time spent on wheel replacement is also saved.

2.More stable quality, effectively reducing the cost of consumables.

Our spray gun has a storage for the polish paste, which allows for regular and quantitative spraying, while avoiding the problem of excessive spraying due to nozzle wear, thus ensuring the stability of the polish quality.

The high-pressure jet allows the polishing slurry to fully penetrate the polishing wheel, saving 25 percent of the waste caused by the high-speed rotation of the wheel.

Effectively avoid the waste caused by the application of a solid polishing paste to the end, which is too short to hold and cannot be continued.

High-pressure injection, liquid polishing slurry spray on the surface temperature of the polished wheel rim has a cooling effect, effectively avoiding overheating caused by the cellulite phenomenon in the workpiece, and can increase the life of the polished wheel by 10 to 20 percent.

3.High pressure system support, low installation and maintenance costs

The gun body is supported by a high-pressure system, and the pressure is not required to rely on a high-cost pressure supply system, but only a low-cost one. As a result, maintenance costs are also lower and there are savings in pipe installation costs.

The range of high pressure spraying can be up to 24 “wide, without the need for high cost slide equipment, and the overall installation cost can be saved.

The high pressure is generated in the body of the spray gun, and the pressure of each gun is the same, and it will not be different because of the length of the air pressure pipeline, or there will be pressure loss.

4.Reduce dust production and improve the polish environment

It can effectively spray liquid polishing on a polishing wheel, reducing dust generation, reducing air pollution and improving the polishing environment.