This article is also available in the following languages:

Tiếng Việt

繁體中文

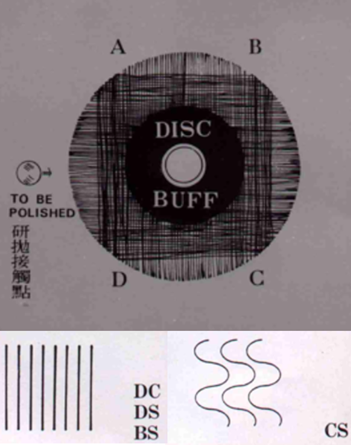

The construction of polished wheel is divided into three main types:

1. Sewing wheel (stitched)

This type of cloth wheel is generally cut from chino, coarse cloth, non-woven fabrics, and fine plain cloth as the raw material, and is sewn with strong stitches. Stitched lines are generally concentric circles, spirals, and direct radiation, with relatively strong grinding forces. Specifications can be customized based on the size provided by the customer.

2. Airway buffing wheel (air-cooled buffs)

This type of cloth wheel is generally made of fine yarn cotton or cotton heavy cloth or canvas as the raw material. Using the 45 degree Angle Line cutting method, the whole is made in a ring shape, with the center plate mounted in the middle.

Because it is cut at 45 degrees, the fibers do not fall off and the cutting is efficient when grinding and polishing.

This cloth wheel is moderate in hardness and has a good softness, suitable for polishing flat surfaces, or for high and low drop products. Irregular creases can act as a cooling effect during polishing.

3. Buckle wheel (non-stitching wheel)

This type of cloth wheel is generally made of fine soft cotton, and buckled cloth wheels are generally divided into two kinds, poplin and anti-puffer. The difference is that the anti-puffer has a higher degree of hardness and density than the poplin, and a greater grinding force, but is also more resistant to wear.

This type of cloth wheel is generally used in the final mirror polishing process, and has a good softness and slight grinding force, and is suitable for polishing workpieces of complicated shape, or for fine polishing of small pieces.

*Considerations before using a polishing cloth wheel

1. In order to get the best effect out of the polishing wheel, the material and size of the polishing cloth wheel should be determined according to the polishing machine.

2. The size of the polishing wheel is determined by the power of the polishing machine motor, and the aperture of the polishing wheel needs to be matched to the rotation axis of the motor.

3. The polishing wheel should be placed in the middle of the rotation shaft, and it is well to remember to tighten it with a wrench. Otherwise, it is prone to accidents under high-speed rotation.

4. To ensure a polished effect, the surface line speed of the polished wheel should be uniform. If the polishing wheel is too large to match the smaller motor, the line speed will be significantly reduced when polishing, and the polishing effect will also be affected.