This article is also available in the following languages:

Tiếng Việt

繁體中文

Wheel Material Classification

1.Steel wheels

Steel wheel hubs are simple to manufacture and low in price. However, it was heavy, had a large inertial drag and poor heat dissipation performance. And wheel styles are common, commonly used in commercial vehicles, trucks, or some entry-level passenger vehicles.

2.Carbon fiber material

Carbon-fiber hubs, which are lighter and stronger, are often used in supercars because of their high cost.

3.Aluminum alloy material

Aluminum alloy materials are better at dissipating heat than traditional steel hub materials, are lighter, more aesthetically pleasing, and are cheaper than carbon fiber materials. As a result, it is also widely equipped in a variety of vehicles.

Aluminum alloy hubs have sufficient strength and are not easily corroded. The die casting process is simple and can be designed in any shape to meet aesthetic requirements. Polishing and electroplating processes can give it a brighter and cleaner appearance. With a surface anti-corrosion treatment and electrostatic powder coating, it can last as long as new.

With the development of automobile manufacturing technology, aluminum alloy wheels (also known as aluminum rings) have gradually become the standard configuration of all levels of vehicles from the exclusive configuration of luxury models. According to incomplete statistics, small passenger cars with a purchase price of more than 50,000 yuan in the domestic market now have an aluminum alloy hub assembly rate of more than 99 percent.

The Manufacture of Wheel Hubs

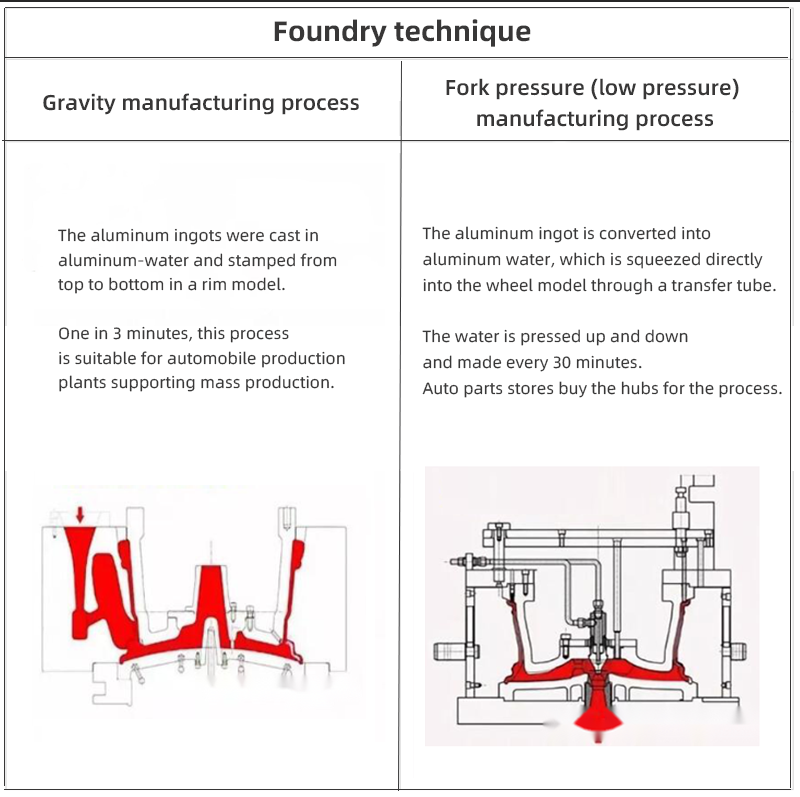

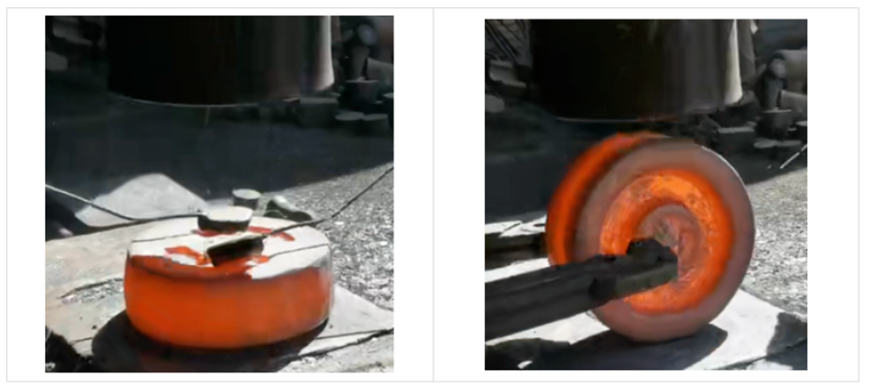

Found

Forging

Polishing Solution

1.Vibrating grinding and polishing machine (smooth machine)

Vibrating grinding and polishing machines use the 3D vibrational principle, double motor vibration, to ensure that there is no dead angle during polishing. It can be used for car hub scraping, oxidation, plating, peeling and other refurbished polishing treatments, grinding and polishing surfaces without scarring and with good brightness, so that after polishing it can be used directly in the electroplating process.

Our company also sells the same machine as the one above. Please scan the QR code at the end of the post to contact customer service.

The steps are as follows:

Rough grinding: Using a compound blue and white ceramic grinding stone, the original scratches, scars, oxidized parts, electroplated peeling parts of the wheel face can be smoothed out.

Fine grinding: Compound resin grinding stones are used to refine the roughness of the wheel hub surface to facilitate this process of polishing.

Polishing: Compound zirconium ball polish stone is used to polish wheel hubs, which can be up to 10K in brightness.

2.Buffer Polishing Machine

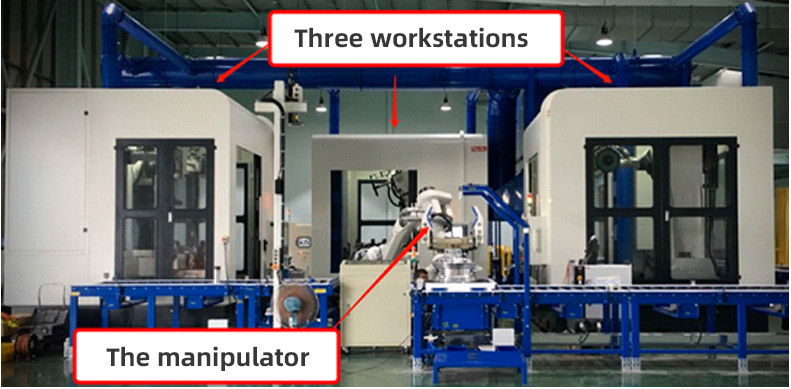

①Polishing equipment: Using a single machine double cloth wheel CNC polishing machine.

Three workstations are responsible for different polishing processes.

The manipulator is responsible for distributing the artifacts to the workstation.

CNC polishing machine, which system is powerful and can provide 360 degree automatic pressure compensation with wheel handling angles, orientation changes and other factors. While the one-step procedure is simple and easy to learn, the polishing pressure at each processing point can be freely defined.

And the writing of the free path program avoids the trouble of cloth wheel repair forming. For a small number of diverse treatments, the processing flexibility is excellent.

The internal layout of the workstation is as follows

The specific polishing steps are:

Sanding: Before polishing, remove tool marks with a pneumatic sander, which will smooth subsequent polishing.

Rough polishing: use a rough-polished cloth wheel for the inner rim: BC-Q18(OD 18 “) or BC-R19(OD 19 “) with rough polishing liquid: LT-36BP. After the rough polishing, the wax is not sprayed over the section, and the rough polish is removed by a cloth wheel during the polishing process, so that no rough polish is left to affect the quality of the subsequent fine polish.

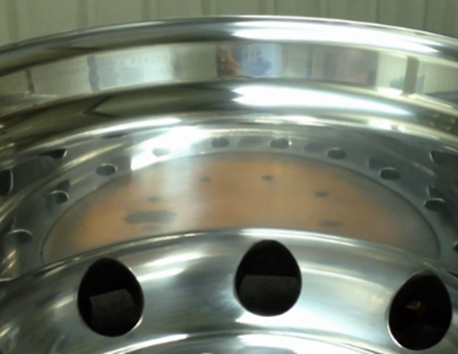

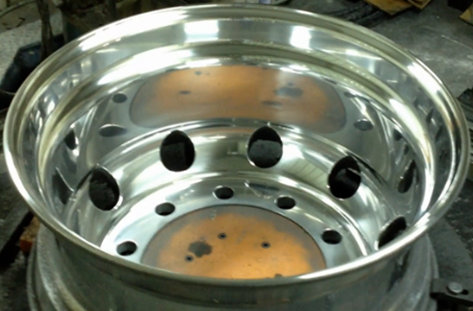

The brightness after rough polishing is as follows:

Fine polishing: A fine polished cloth wheel inside the ring is used: BC-Q18 (OD 18 “) or BC-R19(OD 19 “) with fine polishing liquid: H76-28A and H89-28A

The brightness after fine polishing is as follows:

This hub equipment capacity data, quote, polishing process and related detailed parameters, as well as analysis of the advantages of imported Spanish Autopulit equipment, etc. Please scan the QR code at the end of the page and contact customer service. We will be able to have a specialist to relate with you.