This article is also available in the following languages:

Tiếng Việt

繁體中文

Grinding and polishing are two terms that often appear together but they have different concepts.

Grinding

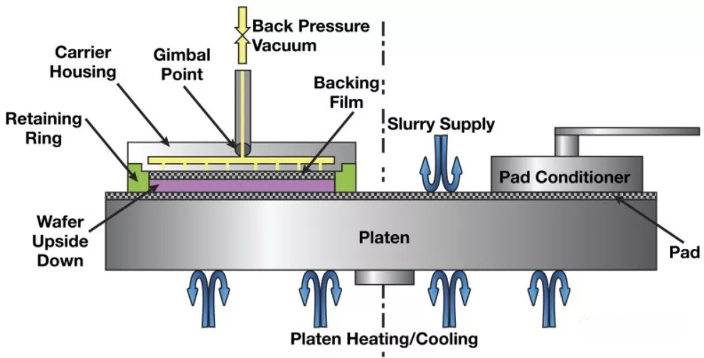

Grinding is a micro-processing technology. It uses the force of grinding tools and abrasives on the working machine, micro-feeding, applying pressure on the surface of the workpiece, and continuously changing it with low-speed grinding to remove the tiny projection on the workpiece, in order to achieve micro-precision machining on the surface of the workpiece.

When the grinding tool touched the workpiece, through the action of modeling and artificial pressure, the grinding process is performed by itself and only on the unevenness of the workpiece surface, so that the grinding tool and the workpiece are mutually corrected, to gradually improve the appearance of the workpiece.

The processing accuracy of ultra-precision grinding is mainly determined by the contact properties and pressure characteristics between workpieces and grinding tools, as well as the shape of the relative motion paths, which can be said to be irrelevant to the accuracy of the relative motion machine.

Advantage of Grinding

Compared with other surface treatment technologies, grinding has irreplaceable advantages. Ultra-precision grinding has higher processing accuracy and quality than cutting, more suitable for planes production. And the equipment of grinding is simple and convenient operation, high processing accuracy.

The other advantage of grinding is its great adaptability.

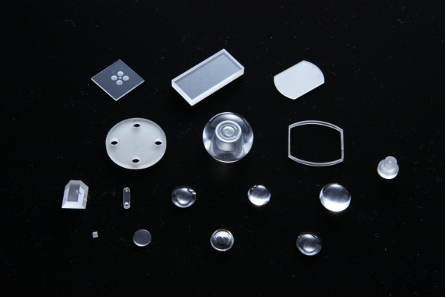

It can process different kinds of solid material, like various metal materials, semiconductor and glasses, etc. Also, shape planes, holes, circles and silicon wafer…such kinds of general solid material.

Polishing

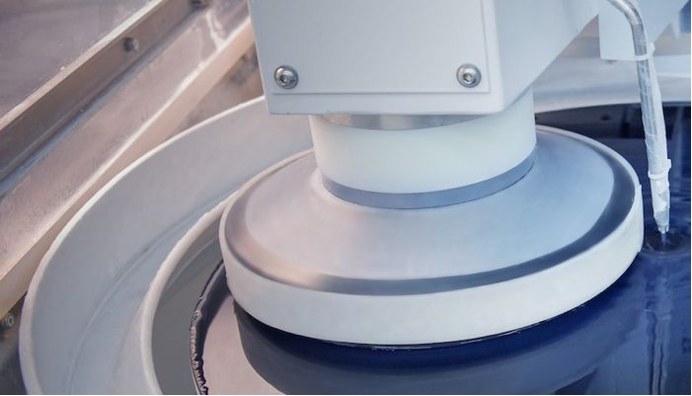

Polishing is a processing method with certain abrasive properties that using low-elasticity polishing wheel or a low speed rotating polishing wheel with soft elastic or high-elasticity, sticks polishing paste (slurry), to rub the workpiece to obtain a smooth and bright surface.

The polishing wheel is generally made of multiple layers of cotton cloth, wool felt or sisal cloth. Its two sides are clamped with metal plates and the edge is coated with a polishing paste (slurry) that is evenly mixed with micro-powder abrasives and grease.

Because the range of fine abrasive grains that used in polishing is 0.1µm to 100µm; so the polishing cannot improve the accuracy of workpiece shape and size. Its purpose is to gain smooth/mirror surface, and matte wire drawing effect.

In summary, there are no essential difference between grinding and polishing, they different from choosing abrasives and tool materials. People use to called the process by using hard grinding tools as GRINDING, the process by using soft grinding tools as POLISHING, but actual in ultra-precision machining field, there is no difference between grinding and polishing.