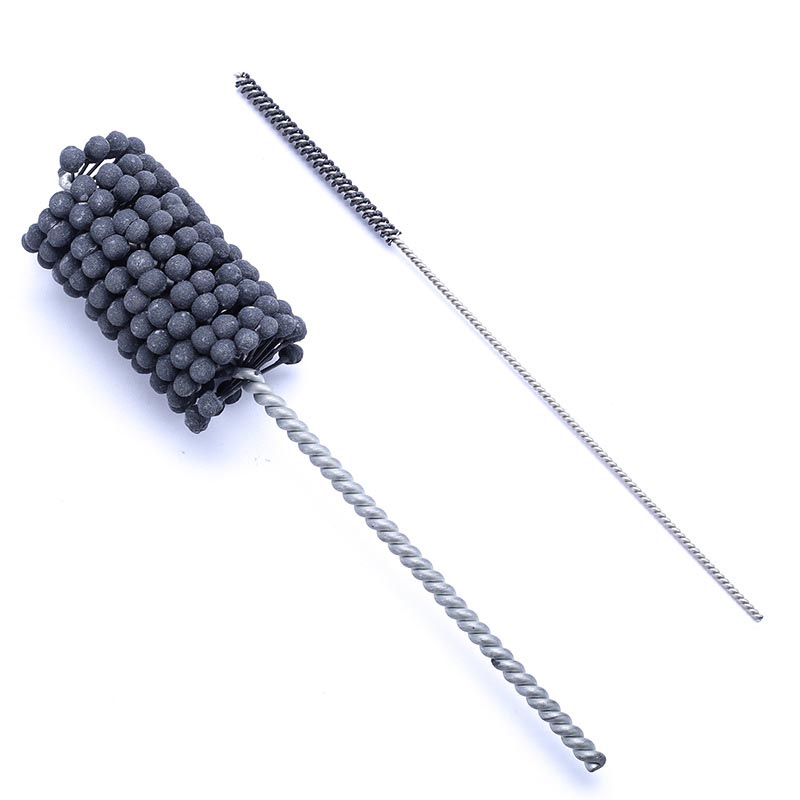

Pipe ball head brush

1. High durability: The even distribution of high-quality silicon carbide grains makes the brushes less likely to fall off, ensuring long-lasting use.

2. High flexibility: The brushes can easily enter complex pipes and holes, adapting to the inner surfaces of various shapes.

3. Excellent deburring effect: The small abrasive balls at the tip of the bristles can effectively remove burrs and impurities from the workpiece surface.

4. Automatic centering and calibration: The brushes have good automatic centering and calibration functions, ensuring consistent and precise processing of the workpiece.

5. Easy to customize: The brushes can be customized according to the processing needs of different workpieces, with suitable bristle materials and head shapes.

This article is also available in the following languages:

English

Tiếng Việt

Pipe ball head brush

Product Specifications

| Category | Parameters |

|---|---|

| Product name | Pipe ball head brush |

| Other name | Ball head polishing brush, silicon carbide ball head brush, abrasive wire ball head brush, grinding ball head brush |

| Product specification | 77*200mm, 105*260mm |

| Product material | Silicon carbide, galvanized carbon steel wire |

| Matchable Devices | Handheld electric drill, bench drill, machining center |

Applicable Industries

Hardware Industry

Sanitary Industry

Furniture Industry

Suitable for industries such as hardware manufacturing, sanitary ware and plumbing, precision die casting, cutlery and cookware, machinery parts and piping, furniture manufacturing, and wood grinding.

Applicable material

Aluminum Alloy Surface

Stainless steel Surface

Iron Surface

Plastic Surface

It is suitable for grinding, polishing, deburring, and cleaning of valve bodies, cylinder bodies, pipes, molds, etc. made of steel, stainless steel, aluminum alloy, plastic, and rubber.

Our Company

MAKERAZE, Located in the high-tech industrial zone of Jiangmen, Guangdong Province, China. We have the professional production technology of buffing and polishing materials in the surface finishing industry for about 100 years.

The industry which we serve is included in Automotive Aluminum Wheels、Door Hardware、Cutlery、Automotive Dashboard、Plumbing Fixtures、Cookware、Lighting、Fireplace Hardware、Medical and Dental、Printed Circuit Boards、Cell Phone Case、Lock Hardware、Musical Instruments、Furniture、Jewelry、Medical equipment…

The products which we supply are including Buffing Bar Compounds、Buffing Liquid Compounds and Spray Gun System、Cloth Buffs、Sisal Buffs、Pressure Tanks、 Buffing Equipment、Grinding Materials、Specialty Abrasives、Non-woven and Coated Abrasive Rolls、Flap Disk、Flap Wheels、Belts and Convolute Wheels、Fuel additives、Buffing Raw Materials、Polishing Materials.

We have a raw material laboratory with R&D ability to give us the well-skilled to adjust the formula of buffing compounds. Regarding the finished products, which are tested by a robotic cell in our appliance laboratory, give us the highest performance by simulated and alternative testing, meanwhile, it gives the best production benefits to the customers. We also support OEM which is required by various brands. And sincerely welcome to have any joint of cooperation and any inquiry.