This article is also available in the following languages:

Tiếng Việt

繁體中文

Faucet is an essential kitchen and bathroom product in home decoration, every family cannot avoid touching a faucet because anyone cannot live without water. However, it is precisely because of its frequent use that we often overlook that the craftsmanship contained in a small faucet is not simple.

The production of each faucet, the intermediate links cannot be ignored, and a finished faucet can be manufactured only after the processes of casting, machining, polishing, and electroplating. Here is a brief introduction to the production process of the faucet.

Molding process of Faucet

Molding refers to a method that making products from molten alloy materials. Injected the liquid alloy into a pre-prepared mold, cooling and solidify to obtain a semi-finished product or part of required shape and weight. The basic shape of faucet is formed after molding.

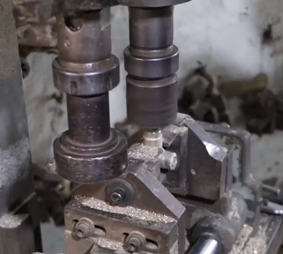

Machining process of faucet

Machining refers to the use of metal cutting machines such as turning, milling, drilling, planing, grinding, boring, and other machine tools to perform various cutting processes on the workpiece to achieve the required dimensional accuracy shape and position in order to meet the requirements of the pattern. After casting, the faucet needs to be machined to ensure the accuracy of the processed dimensions and the smoothness of the processed surface, as well as the sealing performance and durability of the product. At the same time, the processed faucet shell needs a 100% gas test, and all leaks will be discarded and returned to the furnace.

Polishing process of faucet

Molding refers to a method that making products from molten alloy materials. Injected the liquid alloy into a pre-prepared mold, cooling and solidify to obtain a semi-finished product or part of required shape and weight. The basic shape of faucet is formed after molding.

Faucets of different materials need to be customized with different polishing schemes.

Jiangmen Makeraze Technology Co., Ltd. uses the century-old Makeraze brand technology in polishing and other surface treatment technologies. We provide customers with various surface treatment solutions and high-performance materials for a long time. If you have any needs, please feel free to contact us.The following is the polishing solution provided by Jiangmen Makeraze Technology Co., Ltd. for common copper and stainless steel materials in faucets.

The polishing materials required in the polishing process can directly use Makeraze products.

Copper Faucet:

First, using 80# abrasive belt to remove the rough place and pitting; then using 180#, 320# abrasive belts in turn for middle grinding, to grind and trim the surface;

Next, using 400#, 500# abrasive belts for third grinding, make the surface into an almost ideal appearance with clear lines and well-proportioned structure; followed by finishing with #600 abrasive belt for fine polishing, to make the surface into a perfect appearance without any sand holes and pores.

Finally, using cloth buff BC-#47A with polishing liquid 18KR2 (Yellow) to make a mirror surface for the faucets.

Stainless Steel Faucet:

Using #80-#180-#320-#400-#500-#600 abrasive belts in turn for rough polishing of the stainless steel faucet, to make the surface without any sand holes and pores.

Then using sisal wheel OS and cloth wheel BC #51 with polishing white liquid 227H to remove the grinding grains and improve the smoothness and glossiness of surface; and using BC #03 cloth wheel for middle polishing, further improve the smoothness and glossiness of surface;

Finally using cloth wheel BC #37A for fine polishing to finish a excellent mirror surface.

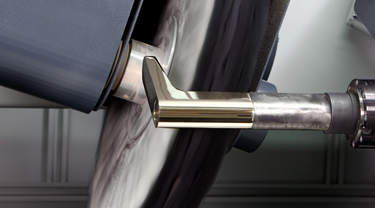

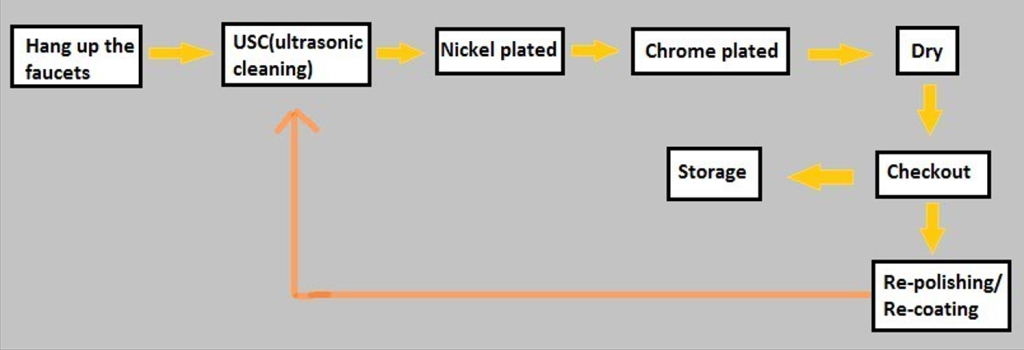

Electroplating process of Faucet

Electroplating is a process that coats a metal layer or alloy on the metal surface to prevent rust and improve wear resistance based on the electrolysis principle. There are various processes and colors for electroplating. The familiar silver faucets is coating with nickel and chrome.

After the above mentioned process and assemble and install, a faucet produced.

The above pictures are from the Internet.