This article is also available in the following languages:

Tiếng Việt

繁體中文

The kitchen is the heart of a home, giving the whole family love and motivation. It is the place where delicious dishes are born. A cabinetry is indispensable in a kitchen, most of high class cabinetries are made of stainless steel.

Today we will talk about the polishing solution for stainless steel cabinetries.

Stainless steel cabinetry is mainly divided into two parts: countertop and cabinet.

With the advancement of steel surface treatment technology and decoration technology, stainless steel cabinetry of various appearances can be produced; their appearance look like a common cabinetry, but the main structure is made of stainless steel.

The stainless countertop takes shape, moisture-proof and easy to clean. The mirror surface of countertop gives people a sense of high-end simplicity and fashionable future, which is deeply popular with consumers.

There are two popular surfaces: matte and mirror, so how can we get the mirror affect?

Mirror finishing

The mirror effect of stainless steel countertops is to polish the stainless steel surface, which is one of the common surface treatment processes for stainless steel.

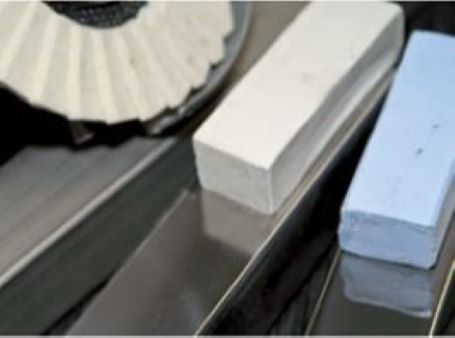

The polishing process is divided into rough polishing → medium polishing → mirror polishing

Rough polishing :

The purpose of rough polishing is to solve the residual grinding marks before surface treatment. It is generally polished by sisal wheels and rough wax.

A calendaring effect formed by the high pressure and high temperature generated by the polishing wheel and the steel, is act on the surface of the stainless steel, using the metal ductility to achieve surface flatness and remove grinding marks.

According to the roughness of grinding marks, we suggest choosing sisal wheels from very hard≥ pretty hard≥ hard≥ pretty soft≥ soft, the corresponding polishing wax suggest choosing: Strong Cutting Black wax(Purple wax) ≥ Cutting Purple wax ≥ Big White Wax(Big Blue Wax).

Under this kind of polishing, it will basically meet the treatment of grinding marks (except for special cases).

Medium polishing:

The medium polishing is progressively advanced from the rough polishing, and the main purpose is to deal with the residual traces of the rough polishing, further improve the surface flatness and gloss.

1.Choosing a rougher pure cotton cloth wheel

2.Polishing wax in turn: Big White Wax≥ Big Blue wax≥ small white wax/blue wax (for higher demand products)

3.Alternately cover the direction of medium polishing and the direction of rough polishing..

Fine polishing(mirror finish):

Fine polishing is mainly to carry out the final refinement of the residual traces produced by the medium polishing, and finally finish a mirror effect.

A few points of material selection should be paid attention to:

1.Choosing finer cloth wheels, generally suggest pure cotton bleached cloth wheel.

This kind of cloth has finer warp and weft and more soft, do an excellent effect for surface.

2.Choosing super bright white wax (different from medium polishing white wax) and super bright blue wax (different from medium polishing blue wax),

the stainless steel surface can achieve extremely high smooth and mirror effect after fine polishing.

A clean cotton wheel should be used to rub the workpiece surface after fine polishing, clean and polish the workpiece after all the previous processes are completed, to ensure that will not have any damage on the mirror surface.

Advantage of Polishing

1.During production of stainless steel cabinetry, there is hard to avoid scratches on the countertop, polishing can solve these scratched and make the countertop smoother and more metallic.

2.The countertop itself is very easily injured by sharp objects, scratches will appear if inappropriate use.

Polishing can effectively enhance the hardness of countertop, reduce the chance of being injured by sharp objects.

3.Countertop of stainless steel cabinetry will become smooth and glossy after polishing.

Using different polishing method according to the situation of countertop and customers’ requirement, mechanical polishing, chemical polishing, electrochemical polishing…these method all can make mirror effect.

4.When finished, it will have a protecting layer on the countertop surface which can better isolate chemical reactions of active molecules such as water and air,

make the countertop more resistant to corrosion and acid and alkali, not easy to have chemical action, thus the service life of countertop can be longer.

The above pictures are from the Internet.