This article is also available in the following languages:

Tiếng Việt

繁體中文

Aluminum products become more and more in our daily life, from the lipstick case to auto accessories, these aluminum products all need to have surface treatment before into normal use. There are various method of aluminum products surface treatment, polishing become the perfect choice because most manufacturers require a bright effect.

We are going to talk about the usual polishing solutions of aluminum products.

Mechanical polishing

It works as follows:

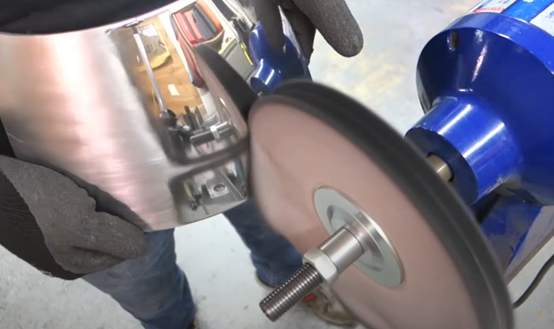

Polishing the aluminum surface on high speed rotating polishing machine by polishing wheel sticks polishing wax.

High temperature generates because the high-speed rotating polishing wheel rubs the workpiece, the aluminum surface become smooth due to plastic deformation.

At the same time, the extremely thin oxide film of the metal surface, is repeatedly grinding, that the surface becoming brighter and brighter.

Why we should polishing?

In the processing of aluminum products, anodizing is usually used as the last process to protect the aluminum parts.

Because aluminum alloys are easily oxidized, although the oxide layer has a certain passivation effect, under long-term exposure, the oxide layer will peel off and lose its protective effect.

Therefore, anodizing uses its characteristics of easy oxidation to control the oxide layer by chemical methods, to prevent further oxidation of the aluminum while increasing the mechanical properties of its surface.

However, before anodizing, it is necessary to check if the workpiece is defective. Any scratch marks cannot be removed after the anodizing treatment, and even be more obvious.

The main effect of polishing is to remove surface defects such as burrs, scratches, corrosion spots, sand holes, and pores on the surface of workpiece, removing the unevenness at the same time, make the surface of workpiece have higher glossy.

Examples:

Jiangmen Makeraze Technology Co., Ltd. uses the century-old Makeraze brand technology in polishing and other surface treatment technologies. We provide customers with various surface treatment solutions and high-performance materials for a long time. If you have any needs, please feel free to contact us. The following is the polishing solution provided by Jiangmen Makeraze Technology Co., Ltd. for two common aluminum products, aluminum lipstick shell, and aluminum pot.

The polishing materials required in the polishing process can directly use Makeraze products.

Polishing of aluminum lipstick Case:

The polishing processes of lipstick case are rough polishing and fine polishing. In rough polishing, we suggest using special treatment sisal DS wheels match with yellow polishing bar contains stronger cutting force, polished by “口” polishing machine.

After rough polishing, the stretch marks produced by machining aluminum can be removed and the surface becomes smooth and bright.

In fine polishing, we suggest using BK treatment bias wheel match with yellow bar, which can effectively polish the grains produced by sisal wheel in rough polishing process; to get a smooth and glossy surface.

Polishing for Aluminum Pot:

The polishing process of aluminum pot includes rough polishing, medium polishing, and fine polishing.

Rough Polishing: we suggest using special treatment meter sisal CS wheels match with yellow polishing bar, can remove the stretch marks produced by machining aluminum and improve the gloss and smoothness of the surface.

Middle Polishing: we suggest using bias wheels with Jacksonlea special sizing cloth and yellow bar, they can remove the the grains produced by sisal wheel during rough polishing, further improve the smoothness and glossy of surface.

Fine Polishing: we suggest using bias wheels match with white bar. The surface of pot will turn to very smooth and gloss after fine polishing.

After polishing, the aluminum parts can obtain a clean surface, improve the quality of surface decoration and the product grade.

The above pictures are from the Internet.