This article is also available in the following languages:

Tiếng Việt

繁體中文

Belongs to the “Hardware Tools”, is a generic terms of coating material, polyamides material, polishing material, which require high hardness, toughness and regular shape, mainly applied to grind, brush and polish workpiece surface.

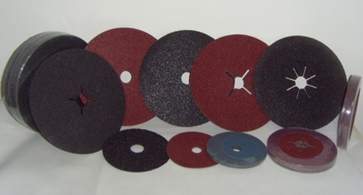

1.Coatings: Fibre discs, Sanding Paper, Sanding Belt

2.Polyamides: Scouring Pad, Nylon Belts, Nylon Wheels, Scotch Brite Combi-Wheels

3.Polishing: Ceramics sand, Polishing Slurry, Polishing Wax, Sisal Wheel, Polishing liquid and others.

Abrasives is a very important for grinding and polishing tools, and there are many kinds to choose, like regular fused alumina, corncob, walnut shell, high frequency ceramics, aluminum oxide, zirconium beads, steel balls, etc. Our company products are made from foreign abrasives with excellent quality.

Application

Through the combination of workpiece characteristics and different polishing materials, it can be used for surface treatment for glass, metal, plastic, stainless steel, jewelry and others, so as to obtain a smooth surface1..

1.No strict requirement for surface finishing.

During burring and deflash process, using polishing material with harder, rougher and stronger cutting force, which can quickly remove the veining.

2.Strict requirement for surface finishing.

During burring and round edge process, using polishing material with certain cutting force, high density abrasives and fine particle size, which can make the workpiece surface smoother.

3.Fine polishing for workpiece surface.

Using special polishing material for such kind of workpice material to make its surface fine, smooth and glossy.