This article is also available in the following languages:

繁體中文

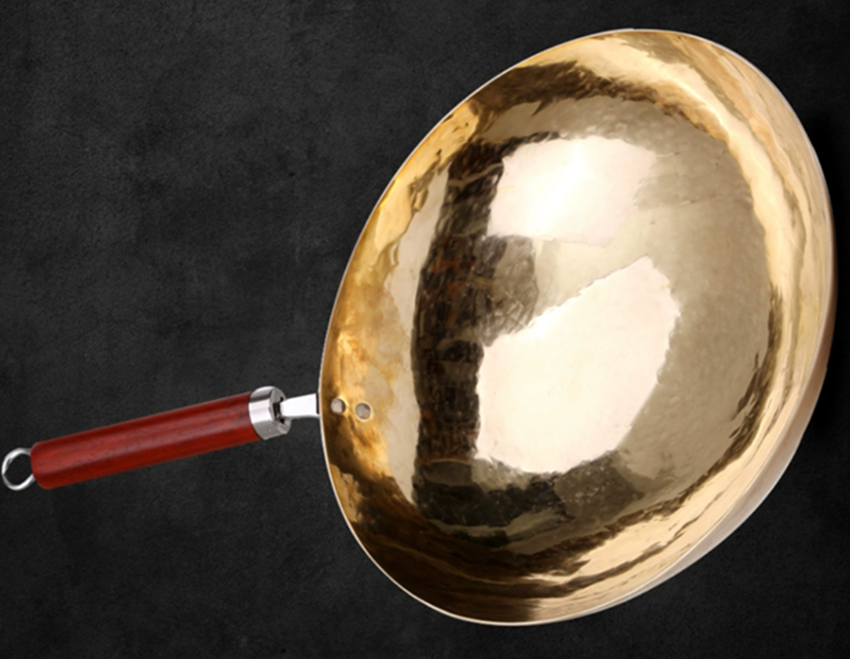

Brass pots are ubiquitous on tables due to their good thermal conductivity, such as brass hot pot, brass instant noodle pot, etc. In addition, brass has good heat transfer, electrical conductivity, calendering, and other physical and mechanical properties. It is widely used in tableware, bathroom, electrical, equipment manufacturing and other fields.

Brass, however, is prone to oxidation and discoloration in the air. If the copper is not treated in a timely manner in the production and processing of surface oxidizers, or if its surface protective layer is worn off, the copper is highly susceptible to oxidation and discoloration, even to black, long patina.

To improve the corrosion resistance of brass and improve the effect of surface decoration, the copper should be polished after cleaning and finally passivated. This article will show how brass pans are made and polished.

Production

First, fill the mould with sand first, make the mould and set it on fire, then pour over the brass liquid, and when cold take out the cast brass pan.

Second, the cast brass pan is again heated and quenched in water to enhance the hardness of the pan and clean the surface of sand.

Third, plastic repairs to the interior of brass pans lay a good foundation for subsequent polishing of the pans.

Polished finish

First, polish the bottom of the brass pan with a sisal buff.

Second, after the excess edges of the cast brass pan have been knocked off, many of the edges and corners of the pan body will remain, and it will be necessary to smooth it out with a sanding band.

Third, use a sisal buff to rough up the perimeter of the brass pan, removing traces from the surface casting and revealing the brass color.

A cloth wheel is then used to polish the pan to give it a brighter and smoother surface.

Finally, treat the inside of the brass pan with nylon wheels.

In this way a beautiful brass pan was made.

Our company has extensive experience in polishing, there are relevant cases in the polishing process of “copper parts”, and can provide customers with complete polishing solutions. If you have a need, you can contact our customer service by scanning the QR code below.