This article is also available in the following languages:

繁體中文

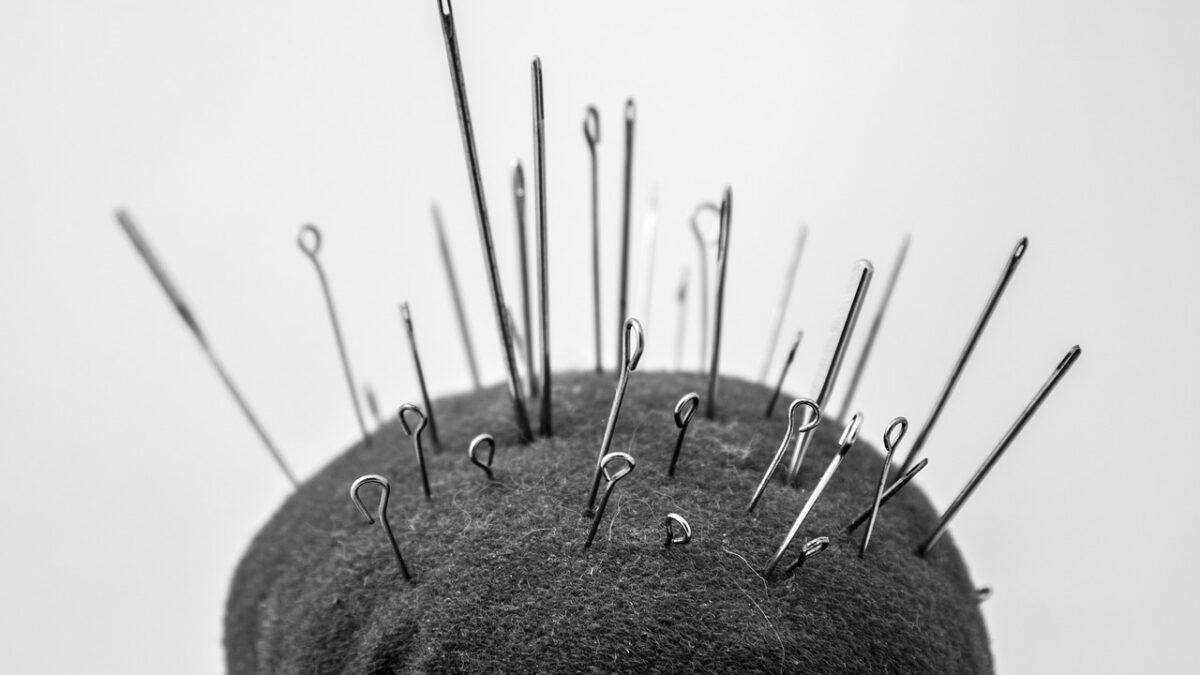

Sewing needles are indispensable in daily life. They are the pointed needles that help us mend our clothes through the fabric. How do they grind? Today we are going to discuss how sewing needles are made.

Raw material for sewing needles

Steel wire

How sewing needles are made

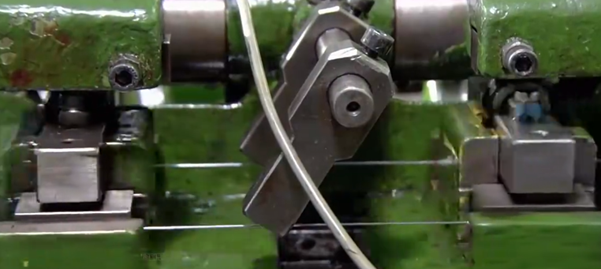

1. Drawing, straightening, cutting

After the wire is introduced into the machine, it is drawn and straightened by the machine, and then stretched to a coarse embryo of suitable diameter.

The proper length is then cut according to the needs of the production.

2.Sharpen

The tip of the needle is ground at different angles using the abrasive belt of the sharpening machine.

This process needs to be performed 5-6 times to achieve a sharp effect, which can be done with our grease stick.Our grease stick extend the life of the belt, make the cutting force more durable, and allow you to get twice the results with half the effort.

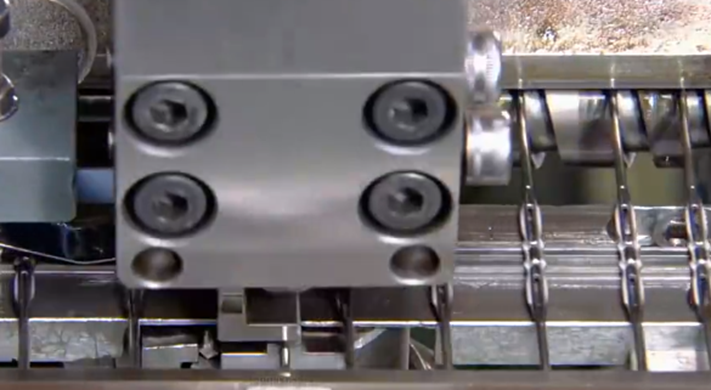

3.Pinhole making, pinhole grinding

Next is the process of making a pinhole, by pressing the pinhole shape of the needle into the middle of the wire for threading the needle. Because of its resemblance to a nostril, it is called a needle nose.

After the pressing is complete, the residue from the nose can be washed off and the sharp edges inside and outside the nose can be polished with a nose grinder.

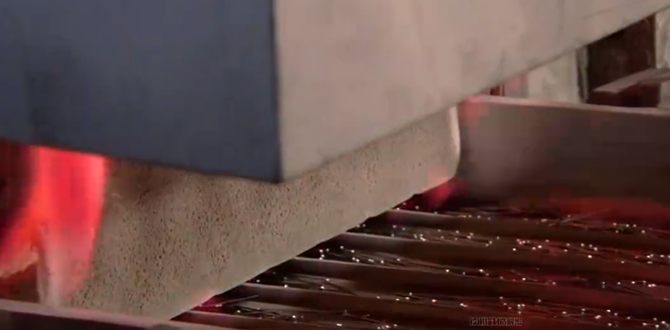

4.Heat treatment

To further increase the hardness of the needle and to prevent accidents during use, it is also necessary to put the needle into the oven for heat treatment.

5. Grinding, brightening, fine-pointing, polishing

Put the needle in a special cloth, add glycerine and polish, then wrap it up and put on a layer of leather.

Rolled in a roller mill for two days to achieve grinding, brightening, fine pointing, polishing and other effects.

6.Cleaning, nickel plating, packing

Take out the polished needles and wash them, then make a nickel-plating treatment and they are ready to pack.