This article is also available in the following languages:

繁體中文

On September 13, Apple launched the iPhone15 series of phones, in which the iPhone15 Pro and iPhone15 Pro Max will for the first time using a new refined brushed titanium metal frame.

Features of titanium alloys

The iPhone 15 Pro uses Grade 5 titanium (Ti-6Al-4V), which is a titanium alloy composed of titanium and a small amount of aluminum and vanadium. Its hardness ranges from 330 to 390 HV. Titanium alloy is a combination of lightweight and durable metal materials that are commonly used in the watch, aerospace and engineering industries. For titanium alloys, we have a lot of relevant experience and articles to share and, if needed, you can click on the article links below.

How should titanium alloys be ground?

Titanium alloy parts polishing manual

Artificial joints polishing in titanium alloys

Do you know what is wire drawing?

Titanium alloys are characterized by high strength, good thermal stability, high chemical activity, and low thermal conductivity. The higher the temperature, the higher the hardness, and it is one of the most difficult materials to process, so it is very difficult to polish.

Titanium alloy raw materials have poor heat dissipation and are prone to knife-edge situations during processing. The wear rate of CNC blades is accelerated, life is shorter, and tools have to be changed frequently. As a result, titanium alloys have high processing risks, poor accuracy, low qualified rate, and high cost.

Wire drawing process

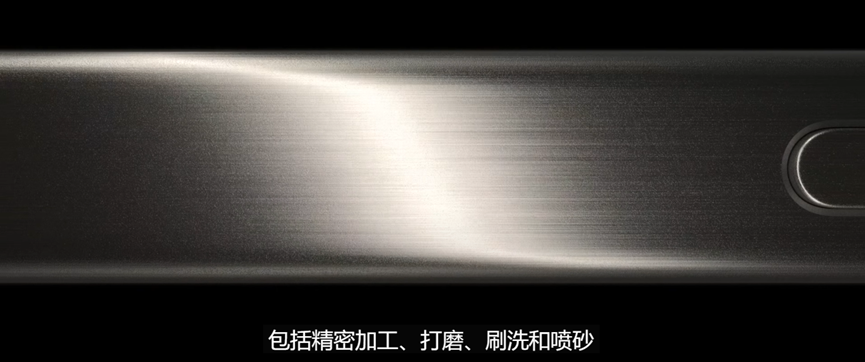

Since the iPhone 15 Pro is made of titanium, Apple has switched from the mirror finish of stainless steel to wire drawing. The drawing treatment effectively improves fingerprint resistance, scratches become less noticeable, and scratch resistance is significantly improved.

Wire drawing process:

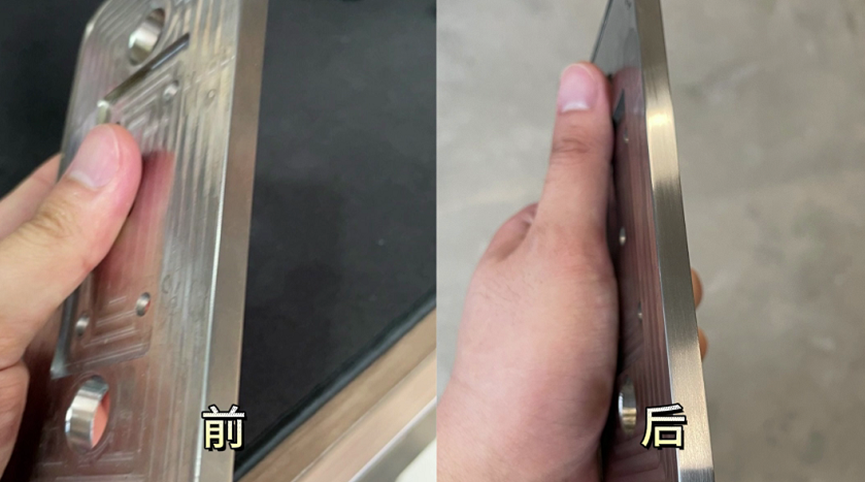

First, the titanium alloy special band #280 was sanded to smooth the surface of the workpiece.

Second, with our special medium-polished wheel and special medium-polished white polish, we can remove the sand marks left by the previous step.

Third, with our special fine casting wheel and special wax of titanium alloy you can throw a bright light.

Finally, use our special drawing wheel to draw the workpiece.

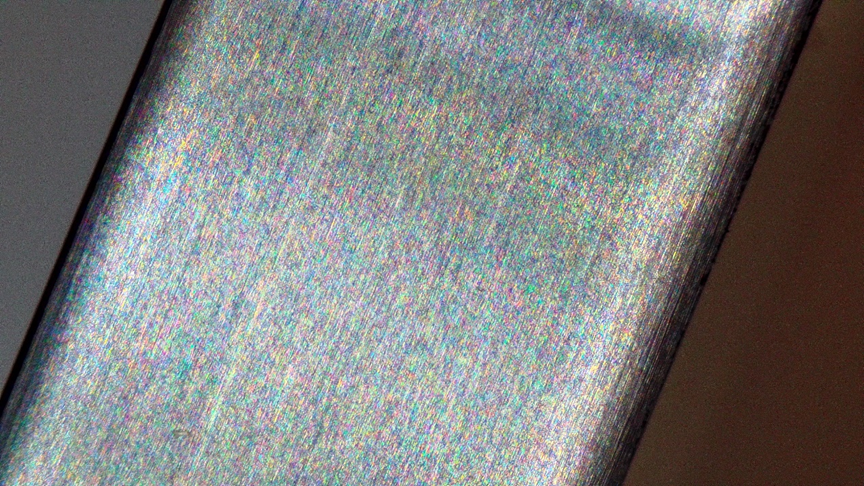

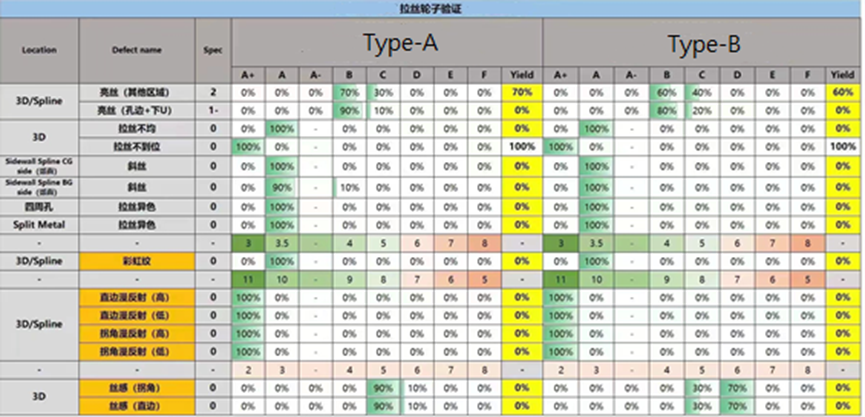

Apple is asking for extreme wire-drawing, like the wire-drawing levels of fine watches like Rolex or Audemars Piguet titanium bodies. Titanium alloy is a very special material, and it is not easy to obtain a uniform drawing effect, and the abrasive used in the drawing wheel is also so special that a little uneven bright filament is not allowed. As shown below, it can be seen by the naked eye, but the instrument determines that it is not eligible. Because you can clearly see a bright filament. If the manufacturer is pursu the ultimate texture, then how to achieve complete uniformity is a branch of learning.

From the 2001 PowerBook G4 Titanium to the Apple Watch Ultra, to the Apple Card made of titanium, and now the iPhone 15 Pro, it can be seen that Apple has put “titanium metal” on the absolute high-end positioning.

The raw material, titanium metal, is not expensive, but production costs are high. However, Apple’s update this time, titanium metal once again appeared in front of consumers with a high-end image. With the increase in industry discussion and attention, the maturity of the industrial chain to reduce the cost of titanium alloy, I believe that there will be more other manufacturers using the same material, but also help to enhance the influence of their products.

* With extensive experience in polishing and related applications in the polishing of titanium alloys, we can provide customers with a complete polishing program. If you have a need, please contact our customer service by scanning the QR code below.