This article is also available in the following languages:

繁體中文

It is well known that titanium alloys have excellent mechanical properties and mechanical properties. For example, high intensity, low density, non-magnetic, high temperature resistance, small coefficient of thermal expansion, good corrosion resistance, no brittleness at low temperatures and a series of advantages.Titanium alloys are widely used in aviation, navigation, chemical industry, weapons and equipment, and are now also used in smartphones, wearable devices and other carriers.

3D printing technology can produce multiple complex shapes of parts, shorten manufacturing time and reduce production costs. Second, 3D printing can also be used directly for repairing and manufacturing parts.

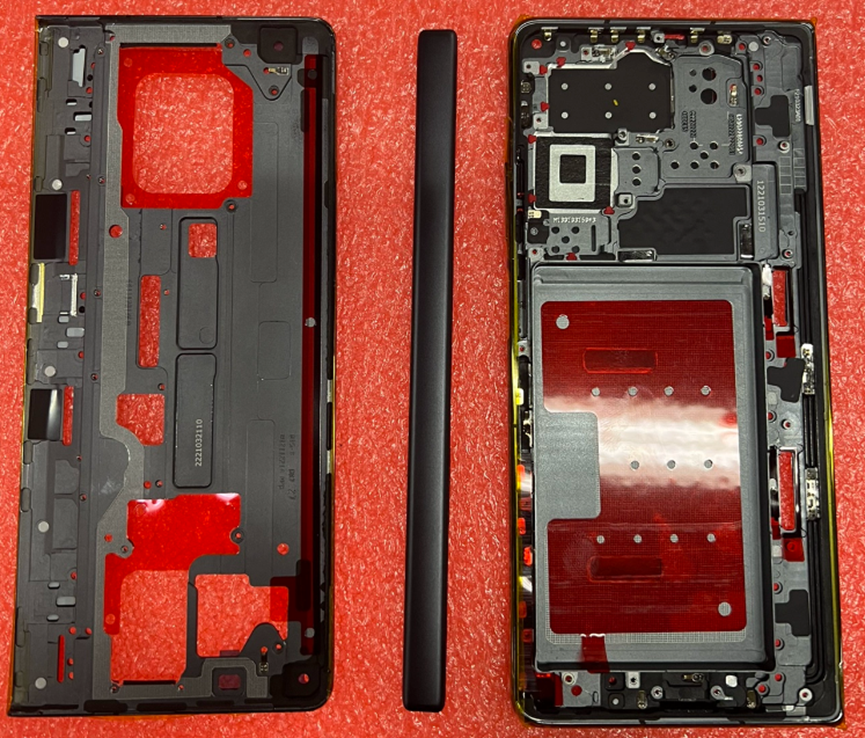

As a result, Huawei and Apple have successively adopted 3D-printed titanium alloy parts for electronic products. Now the MagicV2 axle cover structural parts of the Honor folding screen mobile phone are made using a 3D metal printing process. After this rough processing process is completed, the surface is still relatively rough and requires further polishing to improve the accuracy and finish of the workpiece.Coincidentally, Apple’s Apple Watch Ultra smartwatch, which is said to be released in the second half of this year, is also expected to have some titanium metal mechanical components made from 3D metal printing. Apple began laying the groundwork for 3D printing a decade ago, but it was not until this year that titanium alloy 3D printing was used in bulk for the mobile phone industry for the first time. Well-known Apple analyst Guo Mingji revealed that IPG Photonics is the exclusive supplier of Apple Watch Ultra laser parts, and the printer suppliers are two domestic company(contact us for details if need). If shipments go well, Guo said he believes there will be more Apple products using 3D printing.

Metal structural components of electronics are usually based on stainless steel and 6-series or 7-series aluminum alloys, with the former not being dominant in weight and the latter being generally harder. Although titanium alloys have the advantages of hardness and weight at the same time, they are difficult to process and have low qualified rate. This article will explain how to polish a 3D printed axle cover structural part.

Polishing workpiece

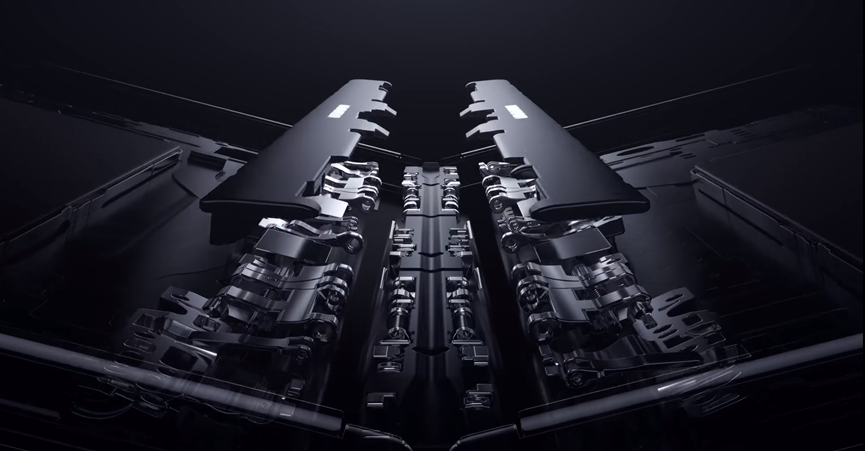

3D printed workpieces, as shown below

Polishing scheme

Polishing equipment:use a five-axis machine

Polishing step:

1. Use diamond sponge to sand three processes: #150→#180→#400

2. Polishing two processes: use our special slurry containing immersed blue flat line wheel and thick twill folding wheel, with our special titanium alloy liquid polishing(specific specifications please consult the contact information below)

3. Clean after polishing. Then the surface needs to be sandblasted. (Please consult the contact information below for specific particle size)

4. After the protective film is attached, it is ready for shipment.

The above picture of the process is not convenient to disclose and if you need this process please contact us.