This article is also available in the following languages:

繁體中文

From time immemorial we have been attracted by the ornate appearance of jewels, and laymen have observed whether the stones were firmly set, and the comfort of wearing them. People in the trade will further examine the degree of finish, and from the degree of finish in a piece of jewellery can be seen the degree of workmanship and care that has gone into it.

A piece of jewelry goes from humble to gorgeous, and the most important process is polishing and finishing. Polishing makes every detail more perfect, the arcs of the lines more smooth, and the wearer more relaxed and happy. In addition, polishing can add surface finish to jewelry; At the same time, it can also be prepared for electroplating, and a well-finished surface can be obtained with a good performance coating.

In the process of mechanical polishing, the skill of the polishing master and the matching of the cloth wheel with the wax require a certain level of expertise, as the time required for polishing is so long that it can take a heavy toll on the precious metal.

In what follows, this article will focus on practical cases of how to polish jewelry. The following scheme only applies to copper jewelry, silver jewelry, K-gold jewelry, etc., and does not apply to gold (texture is too soft).

Selection of machinery and equipment.

Because each person’s technique is different, the speed at which the ring is polished and the equipment chosen, there is no set standard. Only for some special surfaces, which require the use of drawing effects, it is clear that a slower rate is required.

Follow up with a selection and use of small polishing machines, followed by a separate article on their introduction.

Precautions before polishing

For jewelry polishing, the first step is rough polishing.

Tools used for rough polishing: polishing machine, hemp wheel, bristle brush, cable, etc.

Rough polishing is to throw away the file marks, clamp marks, drill marks, burrs and the black oxide layer left by welding on the surface of the jewelry metal bracket, and try to throw the jewelry metal bracket flat and coordinated, so that the arc is smooth and the line is smooth to achieve harmony.

Rough polishing is the basis for medium and fine polishing, and if it does not meet the requirements, it can affect the subsequent polishing and directly affect the quality of the jewelry.

Polishing scheme

1.Rough polishing: Some pieces use white wax on a sisal wheel, usually 6 to 8 inches as shown below.

Customers initially used brand A White Wax, which was replaced by our Company’s 751-39W White Wax. His polish master concluded after the trial that the cutting force was good, that there was no odor, and that the wax was not wasted too much.

2. Rough polishing: some pieces are trimmed with a bristle wheel and white wax. Because bristles are sometimes thrown out by the bristles wheel.It is important that the polisher station has a transparent shield or that the person wears safety goggles. Whatever it is, it’s best to wear goggles while polishing.

3.Medium polishing: use green wax on yellow jewelry cloth wheel, usually 6 to 8 inches. Customers usually use brand A green wax B and now use our company’s SBG-905B green wax instead.

4. Fine polishing: for different materials and different needs of the surface of the workpiece, use a white flat cloth wheel with different kinds of wax.

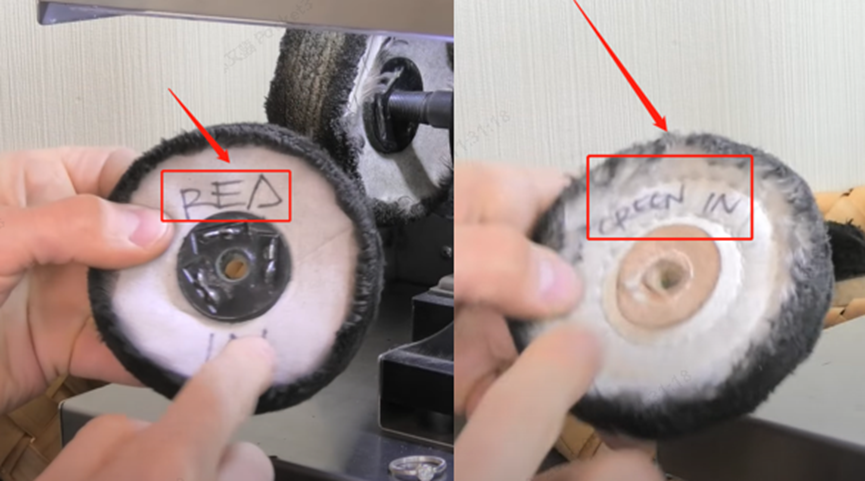

The price of each cloth wheel is not expensive, and it is recommended to purchase several cloth wheels of the same gauge to pair with different kinds of wax. But you should make a distinction, remembering not to mix multiple different wax bodies with the same cloth wheel.

If you do need to mix, clean the cloth wheel first. We have an article on the cleaning of jewelry cloth wheels for reference.

As follows: The master will mark the cloth wheel with which the wax is to be matched, so as not to mix and affect the quality.

5. Fine polishing: for some special requests, white flannel wheels with potato wax will be used for the most extreme finish.

6.The inside of the ring is polish with a woollen cast-iron rod, commonly called a cast-iron rod, and the sides are polish with a woollen wheel. For the loop-tossing part, in fact, there are several steps, which we explain separately. If you are interested, you can also scan the QR code at the end of the post to contact our customer service.