This article is also available in the following languages:

Tiếng Việt

繁體中文

With the continuous development of digitalization, intelligence and networking of high-tech, “3C” products are constantly updated, and consumers have more and more requirements for light, thin, short, small and fashionable portable laptops.

The laptop case is mainly made of three materials, including ABS engineered plastic, metal alloy and composite fiber.

Among them, magnesium alloy is by far the lightest structural material used in industry. Currently, according to incomplete statistics, the magnesium alloy material is commonly used as the casing of mid – and high-end ultra-thin or small-size notebook computers, digital cameras, tablets, mobile phones, etc. It is recognized by mainstream brands and consumption is on the rise.

Magnesium alloy as laptop case advantage:

01 Low density

With a density of about 1.8g/cm³, magnesium alloy is a kind of lightweight metal structural material, which can better meet the requirements of portable products that need to reduce weight.

02 Good heat dissipation

Due to its superior thermal conductivity, the magnesium alloy can quickly dissipate heat sources and timely dissipate heat generated by the CPU and other electronic components, thus reducing system instability caused by overheating of laptops.

03 Excellent electromagnetic shielding

Magnesium alloys themselves have excellent electromagnetic shielding performance, which can isolate various types of electromagnetic interference from outside the machine and reduce the radiation hazard of electromagnetic waves to the human body.

04 Good Seismic Performance

Magnesium alloys have good energy absorption, good shock absorption and isolation properties to protect the normal operation of computer components.

05 Good mechanical processing

Magnesium alloys have a low cut-off resistance and a much higher cut-off speed than other metals. It is easy to cut and reduce processing costs.

06 Recyclable, in line with environmental trends

Magnesium alloy is a recyclable metal. In recent years, many countries have made relevant laws and regulations on electronics recycling, which means that more and more products will use magnesium alloy materials in the future.

The surface treatment process for Laptop

After the forging-stamping-injection-CNC-surface treatment of Laptop structural parts, the surfaces are very coarse, burr, dirty, etc., and must undergo some surface treatment.

Common surface treatment processes for laptops include metal polishing, piano painting, imprinting, plastic electroplating, metal wire drawing, surface frosting, anodic oxidation, and surface spraying. After surface treatment, the hardness of the material can be improved and the texture will be more aesthetically pleasing.

Wire drawing

As regards the sense of beauty, the shell panels are decorated by a process of metal drawing, which is not only beautiful, but is not liable to be scratched, and has a good effect in dissipating heat.

Polishing

There are generally three types of polishing: mechanical, chemical, and electrolytic.

1.Mechanical grinding and polishing is a polishing method that relies on cutting forces and plastic deformations of the material surface to remove the raised parts after polishing and obtain a smooth surface.

Different polishing processes can be classified as rough polishing, medium polishing, and fine polishing. Fine polishing is also known as light polishing. Note: Polishing is not intended to improve the dimensional or geometrical accuracy of the work, but to obtain a smooth surface or mirror finish, and sometimes to remove gloss, i.e. extinction.

2.Chemical polishing is a method of removing abrasion marks and flattening uneven areas of the sample surface by selectively dissolving chemical reagents.

Under certain conditions, nitric or phosphoric acid and other oxidizing solutions are generally used, and the surface of the work is oxidized. The oxide layer gradually dissolves the solution and the surface of the micro-convex oxidizes more rapidly, while the surface of the micro-concave oxidizes more slowly. The same convex oxide layer, diffusing more and more rapidly than the surrounding, dissolves in an acid solution. Thus the surface of the work is gradually flattened for the purpose of improving the roughness of the work surface, or the smoothness and glossiness of the surface.

3.Electrolytic polishing is actually a method of polishing a metal surface using the principle of electrochemical anodic dissolution. Electrolytic polishing is suitable for non-ferrous metals and other single-phase alloys with low hardness, such as aluminum alloys, austenitic stainless steel, high-manganese steel, etc.

* Our company is experienced in polishing, and has cases related to metal drawing and polishing processes. We can offer customers a complete polishing solution. If any questions, please contact our customer service by scanning the QR code at the end of the article.

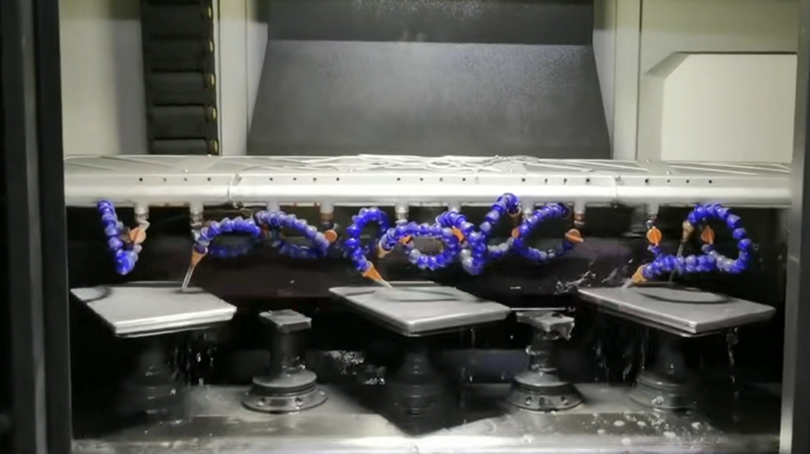

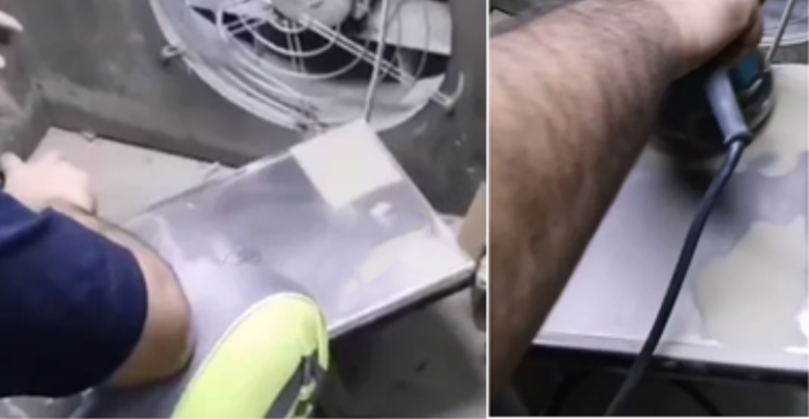

Laptop polishing equipment

Traditional polishing of laptop cases is done by hand.

According to relevant data, China, the world’s manufacturing hub, supplies more than 50 percent of the world’s laptop cases. Relying on manual polishing cannot meet the demand, so now many manufacturers have introduced automatic polishing machines to improve production efficiency.

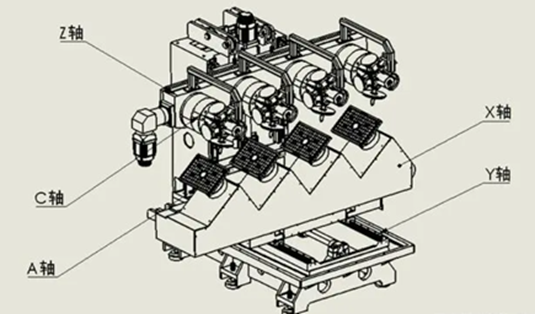

Five-axis machines, manipulators and other polishing equipment are commonly used for mechanical polishing of laptop cases, which not only greatly improves the production efficiency but also ensures the quality of production.

*If you are interested in automatic polishing and want to upgrade the production of enterprises, we can provide you with complete automatic polishing solutions. If any questions, please contact our customer service by scanning the QR code at the end of the article.