This article is also available in the following languages:

Tiếng Việt

繁體中文

In our daily life, the common combination way of metal is welding. Though welding is quick and very convenience, but the surface after welding will have several scars, looks ugly and dirty.

We are going to talk about how to quickly and nicely remove the welding scars. Many customers ask us about this question, we will focus on the removing process of stainless steel welding scars, to introduce the polishing method from the types, relative handhold machine, and polishing consumables.

There are four main common scarred surface conditions according to「Type」:

Polishing for “Vertical Position” Welding Scar of Stainless steel round tube

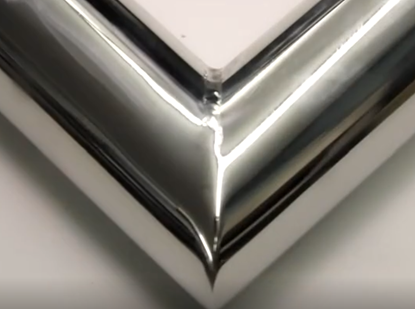

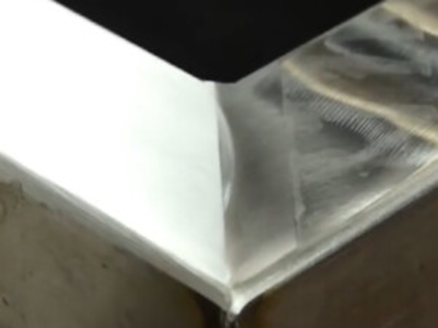

Polishing for “Corner Position” Welding Scar of Stainless steel round tube

Polishing for “Vertical Position” Welding Scar of Stainless steel square tube

Polishing for “Plat Position” Welding Scar of Stainless steel square tube

We talked about the polishing concept for“Vertical Position” welding scar of stainless steel round tube last time, and this article will continue to introduce the polishing concept for“Corner Position” welding scar of stainless steel round tube.

And we will talk about polishing method for other scarred surface type in single article in the future. You can scan the QR code on the bottom to contact us for the article link.

Polishing Solution Advice

1.Using angle grinder with A-frame for sanding belts or double wheel frame.

Grinding step by step from rough sanding belt to fine; smoothing the welding scars by rough sanding belt first, then fining the surface to smooth by fine sanding belt.

2.Using nylon sanding belts to remove the scratches stained in last step.

*It should be noted that we’d better choose different width of sanding belts for different polishing parts. Using wide sanding belts for outside round surface and narrow one for inside round surface. The radian of inside round is narrow; using narrow sanding belts can perfectly match the polishing surface and get a better effect.

*Due to the special shape of stainless steel round tube, using angle grinder with A-frame for sanding belts or double wheel frame can be easier operated by the polishing worker.

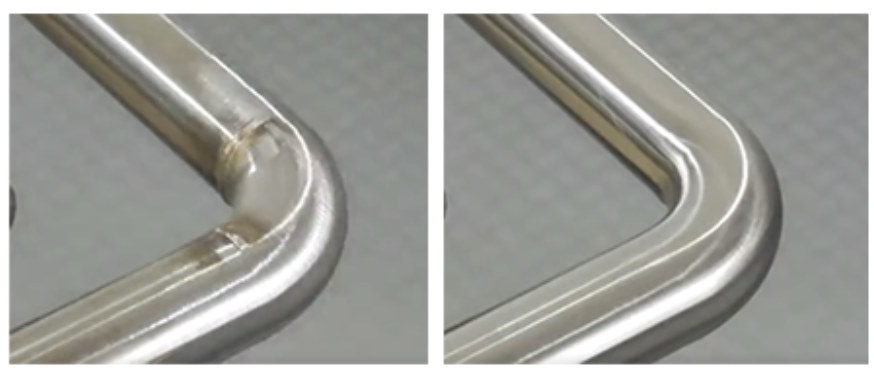

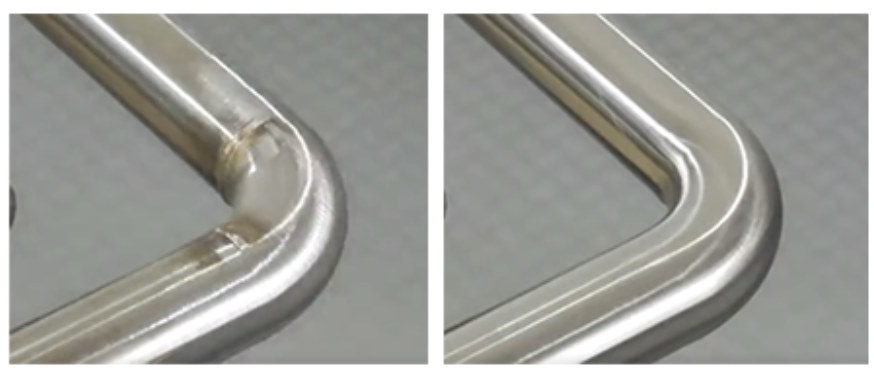

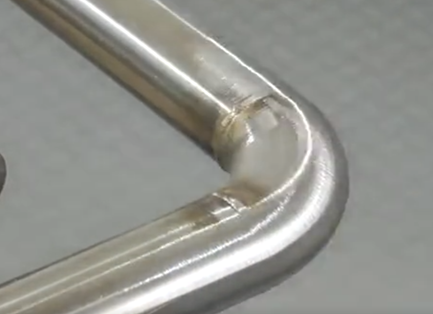

Before & After

The left is the effect after first polishing.

The right is the final effect.