This article is also available in the following languages:

Tiếng Việt

繁體中文

Before we have introduced 1000 version of flap disc wheel, today we will talk about a simplified product of it – angle grinding wheel, is also mainly used in grinding and polishing of industrial production.

Introduction

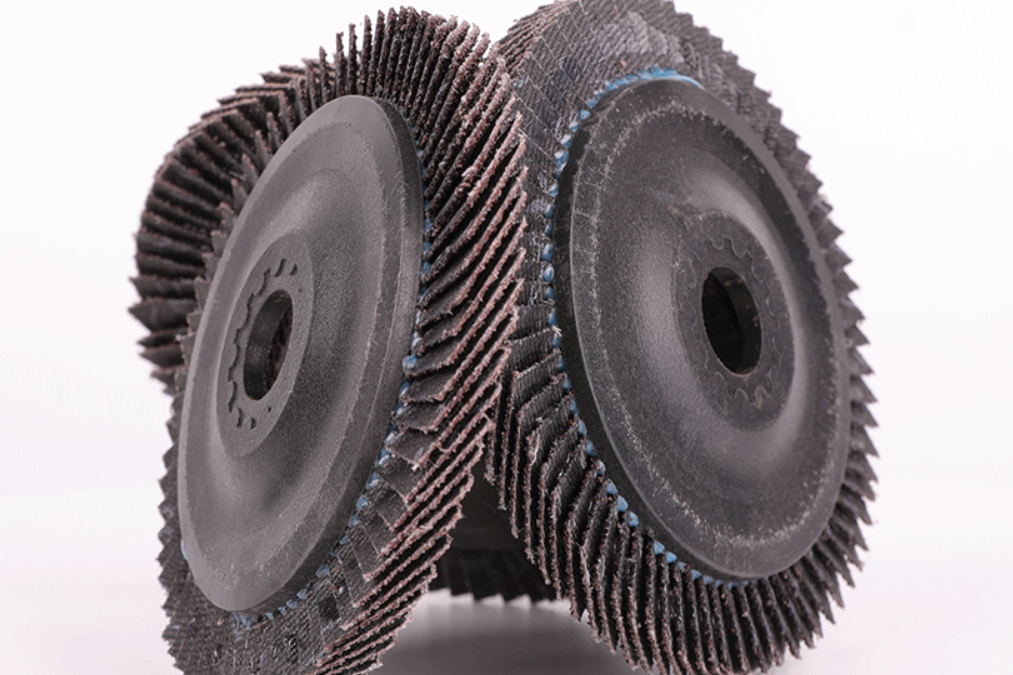

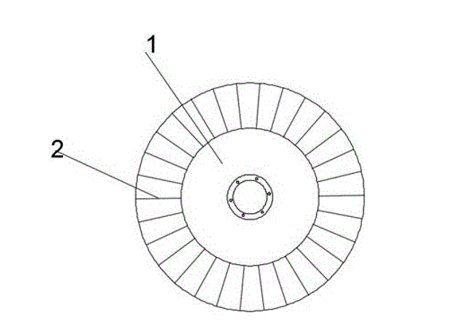

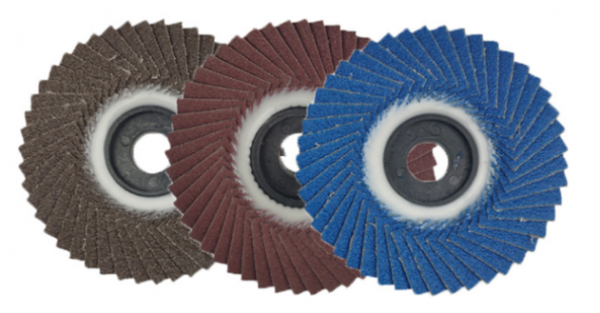

Angle grinding wheel called elastic grinding disc, is made of plastic or fiber mesh cover stick and emery cloth sheets, suitable for angle grinder.

The blades are fanned out; generally there are several kinds, like 36 pieces, 56 pieces, 72 pieces, 80 pieces; particle size between 36#-400#, the most common is 60#、80#. Abrasive material of it has brown alumina, fused alumina, SiC and so on.

Characteristic

1.Its strong cutting force and high grinding rate let it adaptable to material with different hardness cutting process.

2.Wear and tear resistance and cool down fast;

3.Its high hardness let it have good self-sharpness and long service life than other material;

4.Suitable for polishing of rust removal, paint removal, burr removal, grinding welding and flash of stamping parts on ferrous and non-ferrous material.

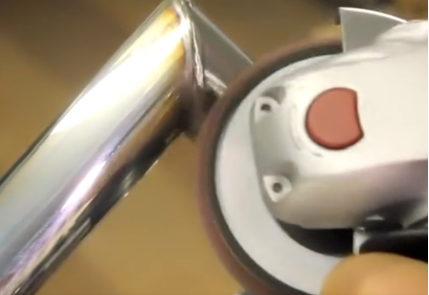

Mainly used in grinding and polishing treatment for various stainless steel and carbon steel structural parts.

Notes

1.Check the equipment before use: check whether the protective cover and the installation of grinding plate is stable;

2.Wear protective goggles and work clothes

3.Do not cut or polish towards others or yourself, prevent accidental injury;

4.The angle between flap disc and workpiece should be at 30°~ 40°;

5.Choose angle grinding wheel from formal manufacturers, do not use some bad angle grinding wheel which is expired or damped;

6.When using the Angle grinder, we should pay attention to the control of strength and uniform force to avoid the phenomenon of grinding pieces breaking, resulting in safety risks.