This article is also available in the following languages:

Tiếng Việt

繁體中文

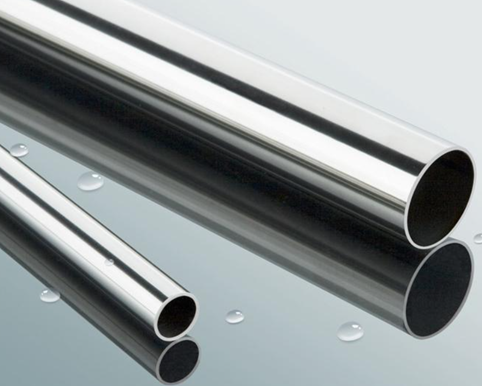

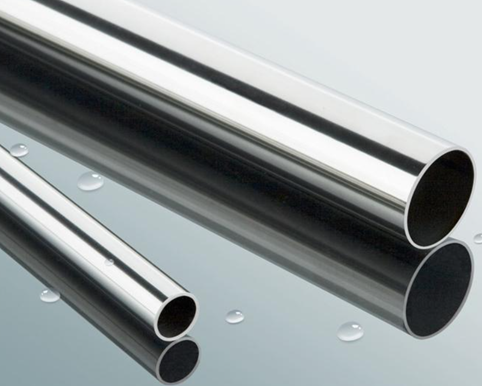

In our daily life, stainless steel material is often used in a variety of places, some will require its appearance clean and bright, the surface requirements are high, in this time, you need to do a mirror polishing treatment.

After mirror polishing treatment, the steel pipe corrosion resistance will become higher, not easy to scale and keep clean.

Standard for Stainless Steel tubes (plates) Mirror Finishing

After polishing and grinding, the surface of stainless steel tube (plate)can be reflected things and people, it can be called “mirror effect”.

NO.1——Hot rolled sheet after forging and descaling, look silver white, without glossy, is a rough and unpolished surface that through hot rolled to a specified thickness after anneal and dephosphorization, often used for manufacturing with low surface gloss requirement.

NO.2D——Passivated surface, cold rolled sheet after forging and descaling

NO.2B——Fog surface, same as 2D, but with better gloss, is a kind of bright surface cold rolled sheet added with a cold rolling process by tumbling machine.

BA——Glossy surface, which deal by heat treatment after cold rolling, the surface become glossier, commonly known as 6K surface. This is the most common surface treatment method, which can also be used as the first polishing step, often used in building materials, kitchen utensils, etc.

NO.3——2B stainless steel plate treated by #80 and #100 Al2O3 sanding belts.

NO.4——After treated by #120(Al2O3) sanding belt and #150(SiC) sanding belt, sheet No.3 surface will have very fine and regular sand mark, which commonly known as “Intermediate grinding surface”.

NO.5——After treated by nonwoven ring belt or nonwoven brush wheel, sheet No.4 surface has very fine and regular lines and with glossy.

NO.6——Sheet No.4 after SiC and oil treated white brown brush wheel grinding process, its surface will has a fine velvet satin and matte finish effect.

NO.7—— Treated sheet No.4 by #280 or #320 SiC sanding belt and cloth wheel with mirror polishing oil.

NO.8——Wet treated BA sheet by vertical wool blended wheel and special polishing solution, its surface without any scratches and reach to a perfect mirror effect, so called”8K mirror polishing surface”. According to different mirror surface requirements, there has ordinary 8K and fine 8K, often used for reflector, decorative surface and other occasions.

HAIR LINE——Sheet No. 4 passes under a slow moving sanding belt #150 or #180 or #240, which direction is opposite to the steel plate travel, and the sanding belt with high pressure contacts the steel plate.

Regular stainless steel mirror surface has a variety of grades, like 6K(BA surface), 8K(NO.8). With higher K value and higher requirements of process, the surface quality will be better and the price of stainless steel will be higher accordingly.

The mirror effect of stainless steel with same thickness generally is not much difference, 8Kmirror surface is brighter. By the way, the mirror effect is worse with thicker thickness, and the processing cost will be higher.

Polishing Step

Rough Polishing

Repeated polishing the stainless steel surface by using 80# or 120# sanding belt, until smooth the surface pits. Do initial treatment of local dents, solder joints left by welding, collisions and deep scratches.

Polishing stainless steel tubes which after initial treatment by using 180# sanding belt, removing the grinding lines leaved by the last step, make the surface free from scratches and collisions.

Middle Polishing

Using #240 sanding belt to polish off the grinding lines made by #180 sanding belt, trim the joints from rough polishing, further refine the marks caused after rough polishing, make the surface free of scratches and brighten.

You’d better carefully polishing in this step to avoid unnecessary scratches and injuries; otherwise it will be difficult to repair in next step.

Fine Polishing

Polishing the stainless steel tubes which after middle polishing by 320# sanding belt; this step can disappear the joints between polished part and un-polishing part, make the surface brighter. Then using 400# sanding belt to polish off the lines made by #320 sanding belt to let the workpiece approach to mirror effect.

Semi-Mirror Treatment

Using our sisal wheel with white polishing wax, polishing the product after secondary fine polishing 4~5 times, can remove the polishing lines caused by 400# sanding belt.

Mirror Finished

By using reciprocating type wide-shaft polishing machine with our disc sisal buffs(GH oil treatment) and bias cut cloth buffs(All cotton &without sewing), match with green fine polishing wax, repeated polishing the 2B stainless steel surface several times, can reach to 7K mirror effect at last.

While for 8K mirror surface, we suggest using special vertical lapping machine, which have mechanical type with single head, or 4heads, or 8heads, or numerical control type with 32heads, match with woolen felt buffs and special polishing liquid for polishing, in this way, can directly polish BA stainless steel plates to a perfect mirror surface, we call “REAL 8K QUALITY”.

The above is an introduction of mirror polishing steps of stainless steel tube (plate). For specific solutions, you can click “Contact us” on the upper right to ask our customer service for requests.