This article is also available in the following languages:

Tiếng Việt

繁體中文

Winter is coming soon, one thing we must have every winter is a thermos cup. The appearance of most thermos cups in the market is treated by wire drawing and painting.

Most manufacturer prefer to do painting treatment for stainless steel thermal cups because it can make various choose of the cups color and appearance, which catch more people’s eye and buying inclination.

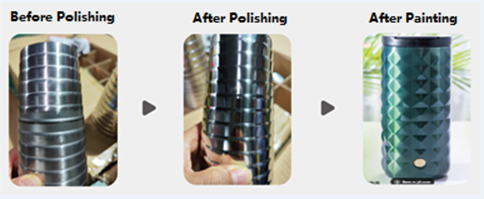

As the saying goes, “If you want to do a good job, you must first sharpen your tools.” If you want a perfect stainless steel cup appearance after painting, then you need to do well in the previous work—-Polishing. After polishing, the cup outside will look fine and smooth (Like mirror), become more conducive to the attachment of spray paint.

Today, we are going to talk about polishing and wire drawing process of these two types of appearance.

Polishing Way

1.Traditional Manual Polishing

2.Mechanical Polishing

We suggest using auto disc polishing machine, which capacity can reduce the manual polisher.

Polishing tools:

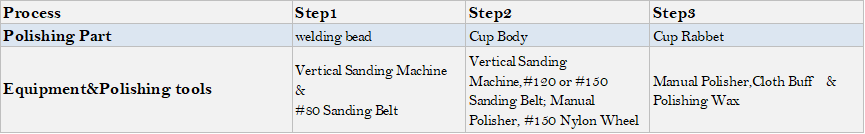

Step 1 : Weld pass treatment

Using vertical sanding machine with #120 or #150 sanding belt, one machine can process 400pcs in one time; one day can reach 800pcs.

(9000pcs ÷ 800pcs = 11.25sets → 12sets of machine)

Step 2 : Cup body

There are two types surface treatment of the cup outside: wire drawing and polishing before painting. Manufacturers can choose suitable polishing treatment based on their ideal appearance.

Wire Drawing

Using semi-automatic sanding machine with nylon wheel (7P, #120), one machine can process 2000pcs in one time; one day can reach 4000pcs.

(9000pcs ÷ 4000pcs = 2.25sets → 3sets of machine)

Polishing Treatment Before Painting

Rough Polishing: Using our company LL Sisal buff with white liquid (Rough), which have strong cutting force, can smooth the cup outside quickly.

Fine Polishing: Using our company bias cloth buff with white liquid (Fine), fast glaring and the polished surface will not remain wax, easy to clean; when painting the cleaned workpiece, the adhesion will be better, thus the pass rate of product also enhance.

Step3: Cup Rabbet

The polishing request is different from the cup outside, it require reach smooth and bright, without obvious wires, scratches, black wires and spot, remaining polishing wax.

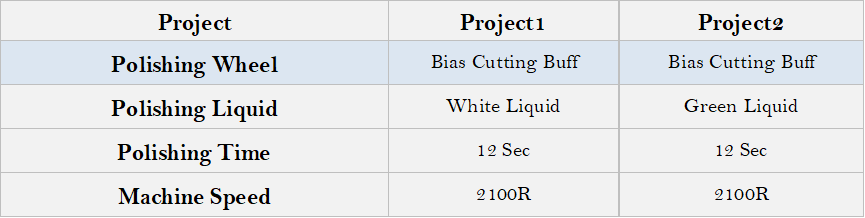

Polishing one time

Compare the glossiness: Project 2>Project 1>Sample. If only polishing one time, we suggest project1.

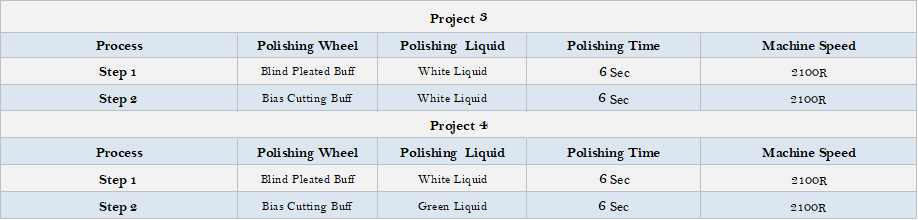

Polishing two times

Our company is experienced on polishing and grinding, having many years actual operating experience and testing concept/process of surface treatment, can customize the best polishing project based on different kinds of quality request.

If you are interested in the above thermos cup polishing project and want to get more detail information, pls feel free to contact us.