This article is also available in the following languages:

Tiếng Việt

繁體中文

Generally speaking, polishing pad can divide into three types based on its filling abrasives, the materials used to make it, surface structure.

Based on filling abrasives:

Polishing pads without filling abrasives:

More steady compare to the polishing workpiece during polishing process.

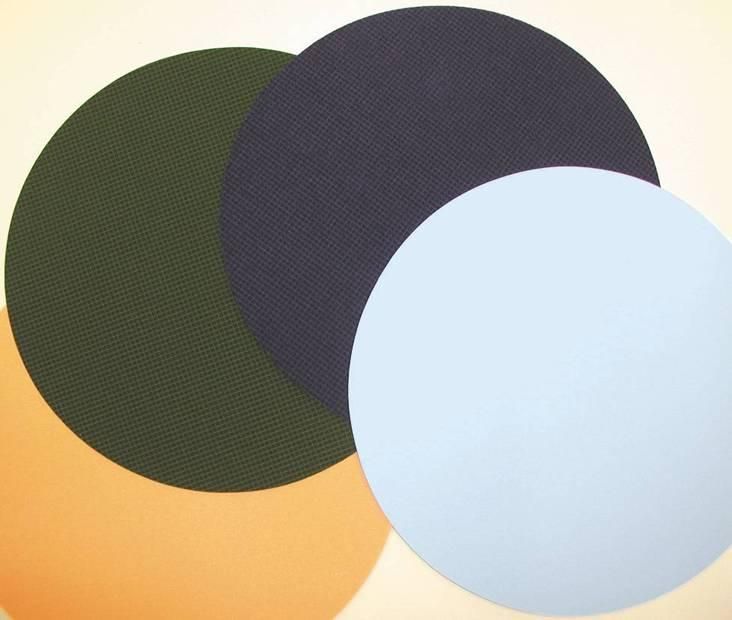

①Yellow for Rough Polishing

②White for Middle Polishing

③Black for Fine Polishing

Polishing pads with filling abrasives:

There have CeO2 polishing pads and ZrO2 polishing pads two types.

CeO2 polishing pads: Has great effect on enhancing polishing speed.

Based on different component material:

1.Non-woven Fabrics

2.Foamed Polyurethane

3.Damping Pad

Based on surface structure:

There have polishing pads have grooves and without grooves.

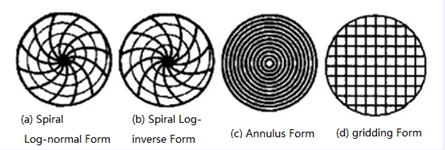

Polishing pads with grooves can divided into below four types according to the groove mould:

Abrasives Slurry can divided into:

Adamas(Artificial Diamond) → Ceramics; Stainless Steel

ZrO2→ Stainless Steel

Al2O3→ Stainless Steel; Aluminum Alloy

CeO2→ Glasses

mSiO2nH2O → Stainless Steel (mirror face)

The Function of Polishing Pads:

1.Effectively transfer the polishing slurry evenly to different areas of the polishing pad;

2.It can take away the residual debris and material produced on the workpiece surface during the polishing process, so as to effectively remove impurities;

3.Effectively transfer and carry mechanical loads required during machining removal;

4.Effectively maintain the polishing slurry film on the surface of the polishing pad, so that the chemical reaction can be fully carried out;

5.To maintain the steady polishing process, surface deformation, can obtain a better product surface, to ensure the quality of products.