This article is also available in the following languages:

Tiếng Việt

繁體中文

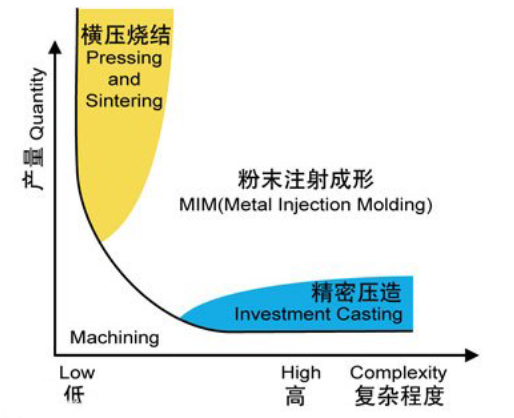

MIM is the short name for Metal Injection Molding, is an advanced technology combined with traditional powder metallurgy technology and plastic injection molding technology.

Mixing the powder with binder and granulate the mixture, then inject into the shape you need, capable of mass and rapid production of various parts with complex geometric shapes.

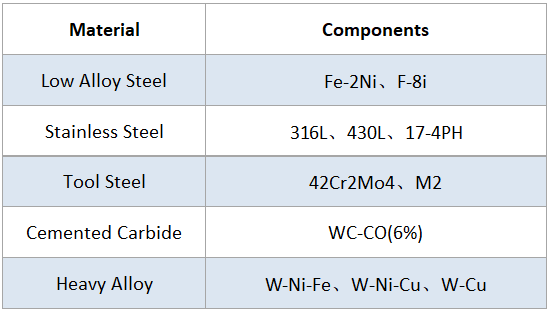

General Materials

Below are general material of MIM:

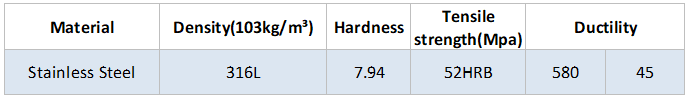

This paper mainly introduce 316L stainless steel.

Production Process

Batching → Mixing → Granulation → Injection Molding → Chemical Extraction → high temperature Debonding → Sintering → Surface Treatment → Product Finished

Application

Mainly applied in aerospace, automobile parts, electronic parts, military industry, daily necessities (watchband, buckle, luggage accessories) mechanical parts, medical equipment and so on.

Why we need polishing?

Because MIM products in the sintering process, the surface of the finished product will be relatively rough, and have slight burr on the surface.

And metal injection molding is mix metal powder with binder and then injected into the model, there may be small stainless steel powder attached on the product surface.

Surface treatment of some products in order to achieve a better surface finishing, not only need to remove the burr on the surface, but also need to achieve mirror effect, such as smart phone metal card slot, volume buttons, bracket above the laptop, etc.

Thus, it usually need to do grinding and polishing or other surface treatment for MIM products. Especially under the rapid development of electronic products, it not only pushes the development of MIM industry, but also for the surface treatment industry.

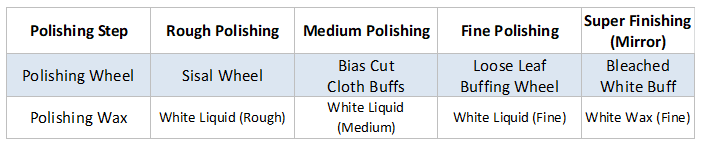

Polishing Step

Mechanical Polishing

1.Polishing Equipment

Using automatic polishing disc machine.

2.Polishing Collation

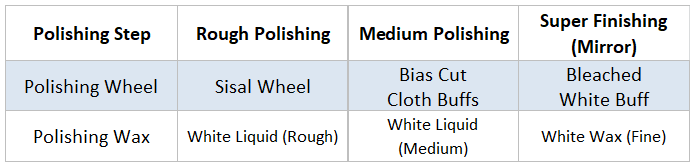

Manual Polishing

Polishing Collation

Polishing Effect

Using the above polishing project, will have strong cutting force when rough polishing, fine lines when medium polishing, quickly brighten when fine polishing; the product will have mirror-black bright surface, clear and translucent.

Our company has rich experience in polishing technology, many years of practical experience and testing programs, processes for workpiece surface treatment. We can customize the best polishing solutions according to different quality requirements. If you are interested in the above mentioned polishing products using for MIM stainless steel parts, you can click “Contact us” in the upper right corner and ask us for the specific polishing scheme.