This article is also available in the following languages:

Tiếng Việt

繁體中文

What does hardness mean?

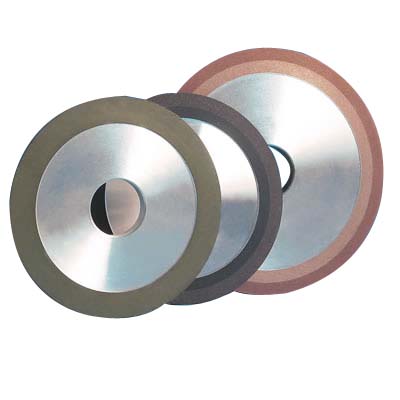

Abrasive wheels divided into different hardness level because the machining demand of different material is different. It is well known that the abrasive hardness means itself material hardness, but the meaning of abrasive wheel hardness is not same as those.

Abrasive wheel hardness refers to the ability of abrasive particles to fall off the abrasive wheel under the action of external force. It is because when the abrasive particle is cut to a certain extent, it will become blunt, and a blunted abrasive particle is useless. A blunted abrasive particle should be fall off by itself under cutting force so that assure the sharpness of abrasive wheel.

In summary, the judge method of abrasive wheel hardness is: the abrasive particles are easily fall off means low hardness, otherwise is high hardness.

Influence of abrasive wheel hardness

Hardness too high

Abrasive particles cannot fall off after blunted, will make blockage of the abrasive wheel. Then the surface temperature of abrasive wheel is too high which will burn the workpiece and lower grinding efficiency.

Hardness too low

Abrasive particles fall off without blunted, will make the abrasive wheel easily wear and tear, then add production cost and affect the finishing of workpiece.

How to choose a suitable hardness of abrasive wheel

The hardness of abrasive wheel should be suitable and consider factors like: the contact size of abrasive wheel between workpiece, the workpiece shape, grinding method, cooling method, type of abrasive wheel binder and so on.

1.For soft and tough nonferrous metals, it should choose softer abrasive wheel.

2.Using harder abrasive wheel to grind soft material; softer abrasive wheel to grind hard material.

3.Different binder in same grinding condition, the hardness of resinoid bonded wheel is 1~2 level harder than vitrified bonded grinding wheel.

4. If using coolant to grind, the hardness of abrasive wheel will 1~2 level higher than dry grinding.

5.When grinding material with poor heat conductivity, we suggest to choose softer abrasive wheel because the abrasive particle cannot be easily fell off if abrasive wheel is too hard.

6.Choosing softer abrasive wheel for grinding fringe and plane, harder abrasive wheel for grinding circle edge.

7.If the rotating speed of abrasive wheel is high, you can choose 1~2level softer abrasive wheel.