This article is also available in the following languages:

Tiếng Việt

繁體中文

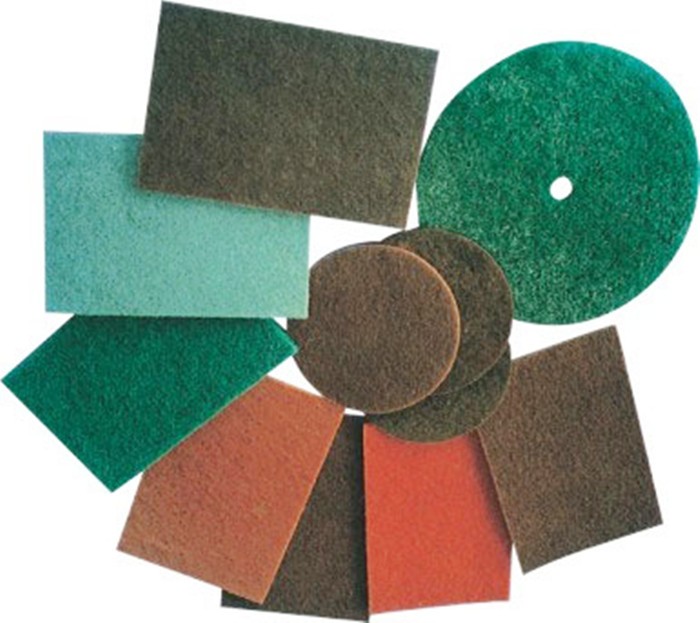

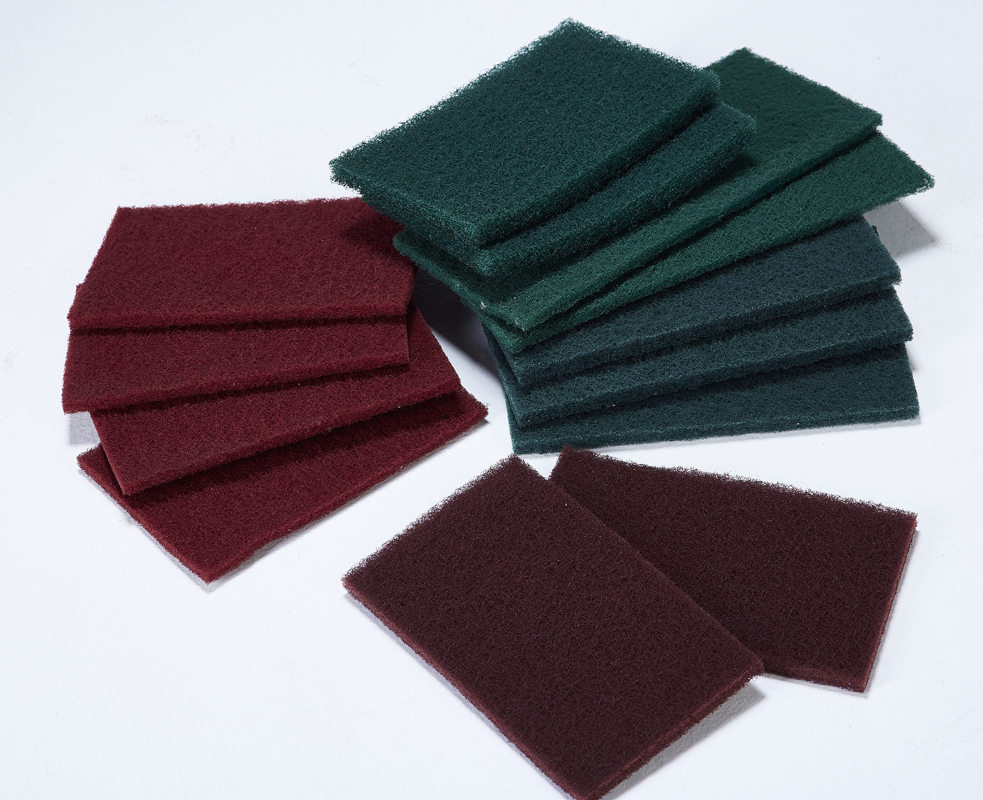

Scouring pad is kind of non-woven fabric grinding product, its open reticular formation structure is using special fibers as substrates and composed of grinding ore.

Using scouring pad for surface treatment is a nice idea that we suggest you to choose suitable particle size of scouring pad according to the workpiece material for first.

Performance

1.Using special fibers as substrates, not only can cut various irregular workpiece because of its excellent elasticity, but also prevent scratches occurred by overcutting, to make the surface more smooth and bright at the same time.

2.Its open reticular formation architecture has larger void space, can cooling down in time to avoid the workpiece surface transformed by high temperature or “orange peel”.

3.Its special structure also can prevent blockage and water resistance, oil resistance, with longer service life.

4.It has self-sharpen grinding performance, its fibers losses constantly with new grinding ores naturally come out during grinding, which can guarantee the product quality no difference.

5.Scouring pad makes less dust and low noise during machining process, more safe and comfortable.

Application

1.Surface paint treatment

Coating on the material surface, like metal, wood, etc., after treated the medium coat and primer by scouring pad, not only strengthen the adhesion between coatings, but also lengthen the coatings service life.

2.High Quality Surface Brushed Treatment

Scouring pad can do surface brushed treatment for various kind of material, like stainless steel, antique copper modification treatment, etc.

3. Burring, Polishing, Descaling, Cleaning

Scouring pad can effectively and quickly remove all kinds of material surface rust, dirt and oxide skin and other attachments, so it is widely used for welding pass cleaning treatment, mechanical maintenance and cleaning.

Scouring Wheel (Flap wheel, Drawing Wheel)

As the good performance of scouring pad, except different shape of scouring pad, hence the derivative scouring wheel (which also known as flap wheel, drawing wheel).

It can meet various needs of surface treatment, like sanding/drawing on stainless steel, aluminum metal, brass, kinds of soft metal, burring of metal parts and the exquisite decoration of aluminum.

What’s more, it will not burn the workpiece to black when rotate on the high-speed, having pretty good effect on high-speed polishing of metal surface, burring and cleaning.