This article is also available in the following languages:

Tiếng Việt

繁體中文

The automatic polishing machine undoubtedly brings great convenience to the polishing production industry. It not only has good polishing effect and stable quality, but also greatly improves the polishing efficiency.

At the same time, the automatic polishing machine also better avoids the problem of unstable production delivery due to the manual loss problem, which is of great help to the production of enterprises.

But you may meet some problems in actual use. Let’s take a look at some problems in the use of automatic polishing machines!

About Polishing Wheels

The selection of polishing wheels is an important part in an entire polishing process. Surface treatment effects such as sanding, peeling, deburring, matte polishing, and mirror polishing are all dependent on it. Therefore, it is extremely important to choose a suitable polishing wheel.

For Material

Different material of workpiece should use their matching polishing wheels, according to different hardness choosing the correct polishing wheels hardness.

For example, choosing the bias sisal wheels for polishing stainless steel which have high hardness; choosing the airway buffing wheels to polish the soft metal products to avoid deformation of workpiece caused by hard polishing wheels.

For Polishing Effect

Polishing can make different effects like sanding, matte, mirror, etc. Sanding is generally done with an abrasive belt or a flap wheel. You can also use a sponge wheel and a sisal wheel in special cases.

The matte effect is done with sisal cord wheels, sisal wheels or flap wheels, etc. As for mirror surface, we generally use bias cloth wheels for stainless steel, and disc cloth wheels for soft metal products.

About Polishing Wax

The use of the polishing wheel should also be matched with polishing wax (paste), only using polishing wheel for dry polishing will damage the product.

There are various types of polishing wax (paste), the distinction and selection of polishing wax are according to the workpiece material, polishing effect and polishing stage.

For example, mirror polishing for stainless steel

Rough Polishing: Recommend common white wax; purple wax or blue wax will suitable for 304 stainless steel.

Fine Polishing: Recommend green wax; you can use our No.5 white wax if you want brighter effect.

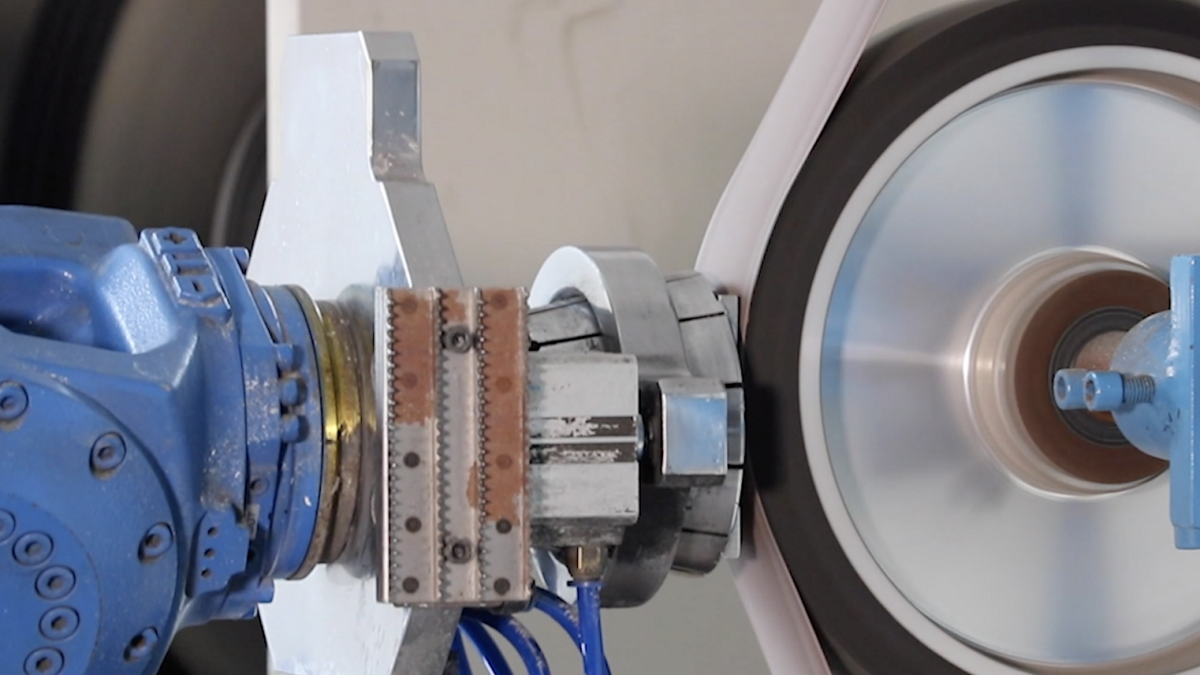

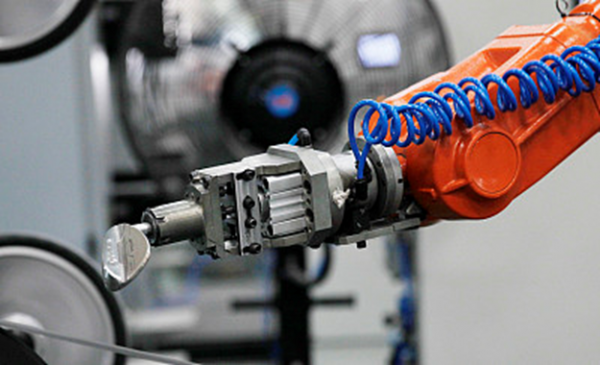

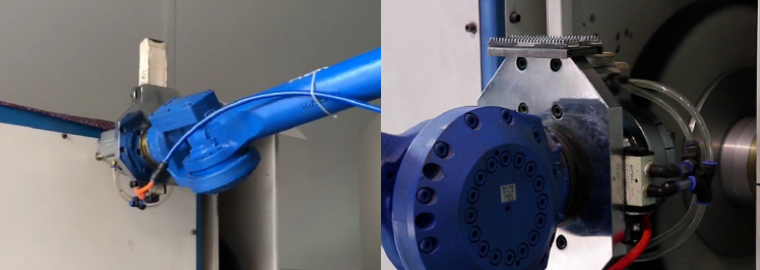

About fixtures

It is necessary to fix the workpiece well when using automatic polishing machine. Tools using to fix products we call it fixture, which usually fixed on the machine working table, three main kinds are vacuum suction fixture, magnetic attraction fixture and common fixture.

Except for the commonly used large-scale products like round tubes, square tubes, flat plates, etc., which can be polished by standard machinery without using fixtures; some irregular or small products must be fixed before polishing, otherwise the product may be thrown away due to the rapid rotation of the polishing wheel, which will endanger the safety of workers.

When using the surface polishing machine for facet products, you need to install a fixture on the worktable

General flat products can use vacuum suction fixture, for iron products can use magnetic attraction fixture.

A suitable fixture can also greatly improve the efficiency of polishing production, avoiding the repeated debugging tests. The manufacture of the fixture needs to be customized to match the shape of the workpiece, and the fit of the fixture with the machine and the workpiece must be considered and coordinated in the design process of the polishing machine and equipment.