This article is also available in the following languages:

Tiếng Việt

繁體中文

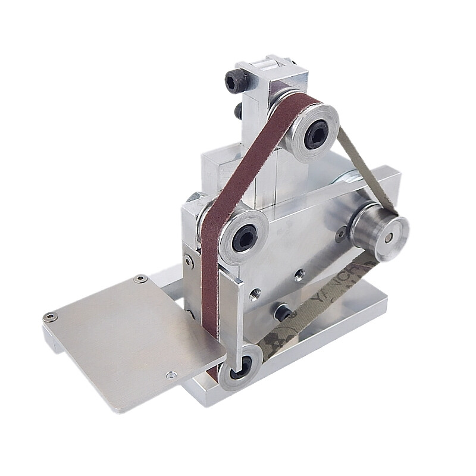

In recent years, with the continuous development of abrasive belts technology, abrasive belt polishing becomes an integral part during surface treatment process for the metal machining industry.

The use of sanding belts

Abrasive belt polishing has good performance in removing burrs, cutting and surface treatment, and is very economical.

Using belt polishing equipment can perfectly handle variety of metalworking jobs such as surface polishing, round polishing, dressing polishing and grinding, R-angle polishing, chamfering and deburring, etc.

As long as choosing a suitable abrasive belt, a high-power motor, and a durable structure, even under a high load, the polishing operation can be carried out reasonably and safely.

The choose of sanding belt polishing machine

Good mechanical equipment can make the whole production process more efficient.

Our company is experienced in grinding and polishing equipment and consumables, and professional technical team services can help customers, providing suitable surface treatment equipment and consumables.

Flexibility

The working efficiency of mechanical equipment is mainly determined by its flexibility. Factories require high work efficiency because they are all mass production, so the flexibility of the equipment is very important.

Contact Wheel

The hardness of contact wheel decide the processing degree. It not only require a suitable hardness, but also need to fit the contour of the workpiece. Generally speaking, the harder and rougher of contact wheel, the higher degree if processing, the more polishing waste; therefore, choosing a soft contact wheel if you need fine polishing.

Driving Wheel

The transfer of force is mainly rely on the driving wheel. The back of the abrasive belt should be able to achieve high contact friction with the driving wheel.

It should also be noted that in order to reduce noise and achieve quiet operation, accurate dynamic balance calibration of the contact wheel and drive wheel is required.

The choose of sanding belts

The quality of the abrasive belt directly decides the effect of polishing is good or bad. There are various kinds of sanding belts in the market; you should pay attention to the grain size of sanding belts (The grain size is relative to the abrasive.)

In addition, the backing of the abrasive belt is also very important. According to the workpiece shape and the hardness of the contact wheel, choosing a suitable backing to ensure meeting processing requirements.