This article is also available in the following languages:

Tiếng Việt

繁體中文

Stainless steel products are widely used in construction decorations/food industries appliances/cookware/kitchen tools and chemical fields by their smooth and firm surface, the characteristics of not easy to accumulate dirt, and easy to clean.

Smooth surface is an important feature of stainless steel products, and it is of great significance to maintain the normal function of stainless steel products. Polishing can reduce the surface roughness of the workpiece to obtain a bright, flat surface. Thus, it is very necessary to polish stainless steel products.

Nowadays stainless steel products are generally have polished during production. Jiangmen MAKERAZE Polishing Material Company surface solution is from a century-old brand , we provide variety of surface solution projects and high performance material. Feel free to contact us for any polishing demand.

Below is our polishing suggestion for different stainless steel products, the mentioned polishing material can directly purchase from MAKERAZE.

The polishing process of stainless steel products usually is: sanding→rough polishing→fine polishing.

Sanding:

Usually stainless steel products need to be grinded by 400# or 600# grinding wheels, choosing the sanding mesh according to different quality requirement, the higher quality require the finer mesh (about 2000#).

The purpose of sanding is to grind the impurity blisters and unevenness during polishing stainless steel parts, removing them to smooth the surface of work piece.

Rough Polishing:

Choosing sisal wheels or hard cloth wheels match with polishing liquid to polish according to the shape of workpiece. Using LL sisal buffs with grey or white polishing liquid 247D\227H from MAKERAZE, is suitable for rough polishing of most stainless steel workpiece.

It can effectively remove the grains of surface treatment like 320#sanding grains or orange peels after rough polishing, so that enhancing the surface flatness and gloss.

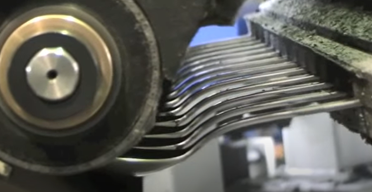

Tableware will go through different angles and equipment in the polishing automation process.

Fine Polishing:

Fine polishing is the key to make the stainless steel products become smooth and bright. Using bias wheel with polishing liquid 323D、426S、479、409、462、336 which from MAKERAZE to process the final fine polishing, all of them can make mirror surface effect.

To make the welding marks of the workpiece surface indistinguishable and bright the workpiece which have finished all polishing process, we should use clean cotton wheels to carefully clean the workpiece surface.

In order to make sure the polished workpiece brightness meet the mirror surface requirements, the clean condition of the cloth wheel is particularly important. In actual production, we needs to replace the polishing cloth wheel in time according to the specific situation.

After polishing and brightening, the stainless steel products are ready to use.