This article is also available in the following languages:

Tiếng Việt

繁體中文

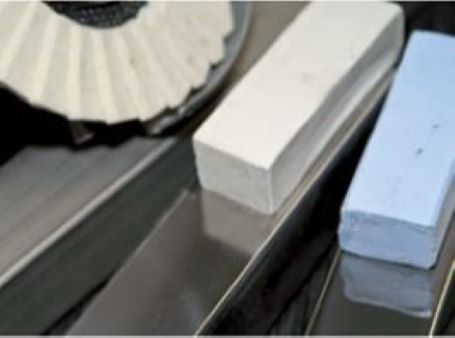

Polishing Wax

Suitable for polishing surface of different material, from rough to fine.

Rough Polishing

Rough polishing usually as a previous step on polishing, it laid the base for the following polishing process by smooth the surface.

We suggest using sisal wheels or hard denim wheels match with white wax for rough polishing.

Middle Polishing

1-2.png)

Middle polishing is the next step follows the rough polishing. The purpose of middle polishing is going to remove the grains produced by rough polishing, let the speed of mirror surface faster in fine polishing step. Sometimes it can process together with the rough polishing if the workpiece original surface is good.

We suggest using flat cloth wheels with 14S, or 16S, even 20S, match with green wax for middle polishing.

Fine Polishing

1.png)

Fine polishing is the final process in polishing process. You can see a workpiece from matte to mirror in this step, also this step can solve the polishing problem if the workpiece appears matte, oxidation or light scratch.

We suggest using 32yarns, or 40yarns, through bleached and refined, to make LL cloth wheels or airway buff wheels, match with small white wax or blue wax for fine polishing, to let the surface achieve bright mirror effect.

Makeraze provides various success and effective polishing project to enterprise, from hardware to automotive, music instrument, from ferrous to non-ferrous, covers almost all industries relative in surface treatment.

We not only provide polishing solutions, but also provide all polishing consumptions and equipment mentioned in the project, let our clients enjoy one-stop worry-free service from customization to implementation.