This article is also available in the following languages:

繁體中文

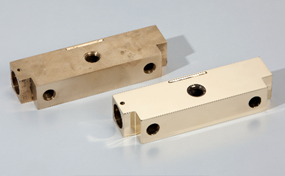

With the rapid development of science and technology, copper is widely used in electrical, light industry, machinery manufacturing, construction industry, national defense industry and other fields, however, because copper is a non-ferrous metal easy to oxidize, if the copper parts are not treated with anti-oxidation in time during production or the surface protective layer wears off during using, copper parts will become very prone to be oxidized or even blacken and have patina.

What should I do after the copper parts be oxidized? How to regain the original brightness of oxidized copper products?

The Secret is — Polishing

To regain the original color and appearance of the oxidized copper parts, we should polish the surface of the copper parts to remove the oxidized copper. Polishing can low the roughness of copper surface and help to get a smooth bright surface.

Jiangmen Jacksonlea Polishing Material Company’ technical is from Jacksonlea USA which with over 100years history. We provide various surface treatment solutions and high-performance materials for customers continuously, if you have any demand of polishing, pls don’t hesitate to contact us. Below is our suggestion for how to polish oxidized copper parts, welcome to contact us for the mentioned polishing consumptions.

How to polish?

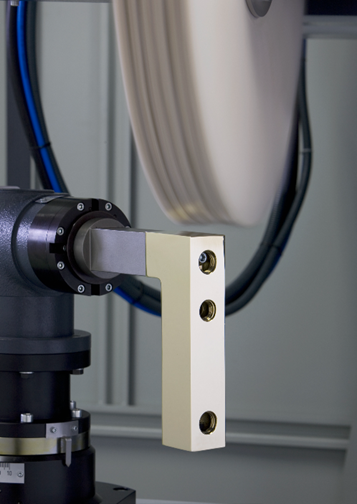

Before polishing the oxidized copper parts, we need to clean the oil stains of copper surface first, then using 80# abrasive belts for rough polishing to remove the roughness and potholes from the surface, and using #180、#320 abrasive belts for middle polishing to grinding and trimming the surface; next, using #400、#500 in turn for third polishing to make the surface into more ideal appearance and have clear lines, proportioned structure; after, using 600# abrasive belts for finishing to achieve the perfect appearance of the surface.

At last, using bias cloth wheel BC-#47A match with polishing liquid 18KR2(Yellow) for fine polishing, which suitable for most fine polishing process of copper products. After the above-mentioned polishing treatment, the copper parts can be regain their original brightness, and can also achieve a good mirror surface.

After the copper parts are polished and regain its brightness, we need to do copper protection treatment— passivation treatment, to prevent oxidize again. Some products require bright beautiful and persistent new appearance, like medical equipment, food industry, tableware, household items, etc. After copper polishing process and passivation anti-rust treatment, can not only make the copper parts look as bright as new, but also effectively prolong their corrosion resistance.

The above pictures are from the Internet.