This article is also available in the following languages:

繁體中文

①

Do not let the cloth wheel polishing in a fixed position.

Because the polished surface sometimes will have directions similar to fibrous due to the cloth wheel always rotates in a fixed direction, especially in the soft metal. So you should polish in different directions cross and overlap to make the surface smooth like painting.

②

Polishing a mirror surface at the beginning and roughest stage (if circumstances allow) Otherwise, you will not get a mirror surface at finer stage.

Pls do not forget that cloth wheel polishing is totally different from traditional polishing in theory.

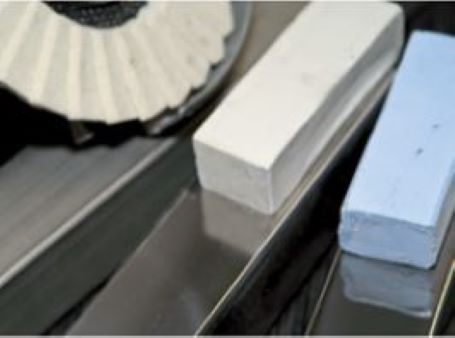

1.png)

③

Cloth Wheel Polishing only suitable for thermoplastics.

On the contrary, it is not suitable for thermosets because they do not soften with elevated temperatures. Using soft cloth wheel with fine wax and light force for first polishing try of soft plastic material since plastic materials are inherently low in hardness or melting point.

We will write other article to talk about polishing for plastics.

④

Materials with hardness above a certain level cannot be polished by a cloth wheel because the temperature required to achieve softening is too high to be achieve.

Generally speaking, some hard materials that easy to be brittle, like glasses, heat-treated steel, tempering treatment, these kinds of materials after harden material surface process cannot do cloth wheel polishing. But some soft metal can do cloth wheel polishing after hardened due to their hardness is still very low.

Brittle materials like heat-treated steel, will have countless tiny cracks (cracked due to brittleness) on the surface and never have a normal mirror surface.

1-2.png)

⑤

Before going into next polishing stage, using light force to make the polishing trails into unobvious trails.

Then it will be easy to polish in next stage.

⑥

If unfortunately appears “non-metallic medium” during the polishing process, handle it by strong grinding tools like abrasive paper to deal with it, and do all over again and pray not to appear again.

This is the formation of mineral nature tiny particles of extremely high hardness due to improper control during the alloy smelting process.

It was a mistake made by last production process, none of polishing process business.

⑦

If there are scratches (visible to eyes) on the material surface during the polishing process, that means it has been dust contaminated by other metals or minerals.

Scratches mean a hard tiny particle that has been ground across the surface of the workpiece by your cloth wheel. And due to the abrasive particles is too tiny, its scratches are invisible, so the scratches must be created by foreign object.

Maybe this cloth wheel have polished that material before, maybe the dust floated in the air…It is very common in metal workshops, especially when without professional dust removal equipment.

The best solutions is to change a new cloth wheel, or scraped the top layer if polluted on the polishing wax, and do the necessary measures to prevent mutual pollution of dust (But it is hard to achieve in actual production, so…)

It is unable to polish a perfect mirror surface in small polishing workshop because it polish everything, so have serious dust pollution, however, the polishing foundries are polishing the same material, they have no pollution problem like workshops.

⑧

There is another very common situation: white fog appears on the surface of the material when polishing by cloth wheel.

Which actual is scratches occurred by abrasive impurities in the polishing wax, it as a plane instead of a line in human’s visual because it is too tiny.

In cloth wheel polishing, except the purpose of making a mirror surface in the first rough polishing, the other stage is going to polish these kinds of fog surface into finer surface.

⑨

The surface of the polished workpiece will have covered a layer of wax (the main component of polishing wax)

Do not specially use solvents to clean it if you will carry out other surface treatment such as electroplating, anodizing, etc. later because wax can isolate the air and help prevent metal oxidation.

⑩

The hardness of the workpiece can never be changed by any grinding and polishing work. In fact, there is totally misunderstood that polished material with mirror surface is easy to be scratched.

Mirror is a state of being completely free of imperfections on a visually visible scale, it will be very eye-catching if there are any visible flaw under this state. But the difficulty degree to be scratched of material has not change at all.

Now that we’ve talked so much, why not try it out now!