This article is also available in the following languages:

繁體中文

Among all grinding and polishing methods, cloth wheel polishing is a magical existence. Today we are going to introduce this unusual polishing method and discuss the operation in general production.

What is cloth wheel polishing?

Cloth wheel polishing means using high speed rotated polishing cloth wheel to pick up the abrasive liquid, apply pressure on the surface of working piece when the surface hardness is temporarily reduced to a certain extent by friction and heat generation, to slash the surface roughness.

If use simple words to describe the cloth wheel polishing technology, that is

“Friction heat, plastic deformation”

There’s nothing need to explain for the “Friction heat “, we would like to explain “plastic deformation” . Everyone played clay when they were kids. Clay is a material that can be easily shaped by applying pressure on it, this feature we called it “plastic deformation”(Plasticity) Material with good plasticity can be easily shaped into various shapes, and this feature can of course also be used for polishing, the process of making a rough surface smooth is also a change of shape.

Why we need ” Friction heat “?

Because metal materials and thermoplastics have better plasticity at higher temperatures and lower hardness, in order to let cloth wheel apply pressure on the work piece to shape easily, then we need to reduce the hardness of work piece temporarily by friction heat. If everything goes well, you can see it is easy to shape the metal like playing clay, even you can push the soft metal as clay.

Below image shows a scar made by screwdriver on the steel alloy and blind holes made by 3mm drill at two sides.

If you still confuse, imagine laying asphalt on the road, asphalt is also a material that decreases in hardness with increasing temperature.

About Polishing Machine

We of course need to have a polishing machine before start polishing.

Polishing machine actual is a electrical machine, fixing the wheel on the motor spindle to rotate.

In fact, there is not much difference between a polishing machine and a grinding machine, who already has a grinding machine can directly install an appropriate polishing wheel to use. If you want to buy a polishing machine, choose a shaft as much as longer will be better. A bulky workpiece polished by a polishing machine with a short axis or a general grinder will be difficult to use because hitting the motor outer cover. (Space for operating is too small)

Generally speaking, the polishing machine used in the polishing workshop is floor-standing type; it drives a shaft as thick as a bat through a belt and opens a big hole in the center of the polishing wheel which matches this thick shaft. The polishing machine is a motor shaft straight out to fix a polishing wheel in common workshops. Since the workpiece will be rubbed back and forth when polishing on the wheel, the polishing machine must place steady on the floor or working platform.

It should be noted that grinder axis and the grinding wheel hole and polishing machine axis and the polishing wheel hole are not just one size, they are common size in principle. So we can make a bigger hole of soft polishing wheel and case the axis if the hole is too big. (Excluded hard grinding wheels)

The most important thing for polishing machines is “power”(Commonly known as “Horsepower”).

Since the workpiece must be rubbed hard against the polishing wheel during polishing, the more powerful motor, the harder the metal material can be dealt with, (still have limits) a motor with low power probably unable to continue working because the relay disconnect by RPM dropped before sufficient plastic deformation has occurred.

In general production, we recommend polishing machine in 0.5HP to polish soft metal material like copper/aluminum/other softer metal; polishing machine in 1HP-2HP for hard metal like iron.The standard answer is that the more power the better.

There are two common ways to fix the polishing wheel of the polishing machine: One is a conical sleeve with screw teeth commonly known as “rat tail”, the advantage is you can directly put on without mind the size of the hole, the disadvantage is it might slide when you polishing very hard. Relatively speaking, it is safer to use nut to lock, only more trouble when you need to change the polishing wheel.

*Due to the large amount of dust generated during polishing, many polishing workers use cardboards to make an appropriate baffle.

About Polishing Wheels

The polishing wheel is a kind of grinding wheel made of various cloth or fibers, different from various grinding wheels for common grinding and polishing, it does not contain any abrasives at all, so the polishing wheel itself does not have any grinding and polishing effect.

The most important thing in the actual use of the polishing wheel is its “hardness” and “density”, it will become tough because of centrifugal force when it rotating. The resistance occurred from rubbed with a foreign object is called “hardness”.

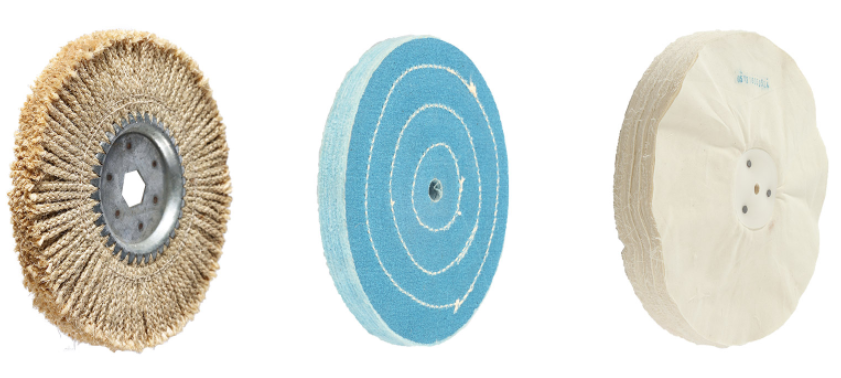

For those who have no concept at all, you can choose the following cloth wheels with different hardness to form a complete polishing set “Rough-Middle-Fine”.

From high hardness to low hardness: Plat Sisal Wheels/Stitched Plat Cloth Wheel/ Non-stitched Plat Cloth Wheel.

Some cloth wheels make of finer fiber like wool, but the roughness of the fiber is not relative to the structural hardness of cloth wheel. Don’t assume it’s only suitable for finer polishing because it’s made of wool, a completely solid wool wheel is almost as hard as a sisal wheel.

Last but not least, using a raker to destroy the friction surface of a new wheel before use to allow the fibers to fluff, the too long lines that constantly thrown out during use should be trimmed off also. In theory, a cloth wheel can only be matched with one kind of polishing wax, using a same cloth wheel to dip different roughness of polishing wax is not recommend (At most from fine to rough). But sometimes it is difficult to avoid in actual production,

so……depend on yourself. If you have high quality requirements, we still recommend one cloth wheels match with one polishing wax.

*Raker(Cloth Wheel collector):

A tool for cleaning the polishing wax on the surface of the cloth wheel, same as a large file.

But please don’t consider that this tool really can completely remove all foreign objects on the cloth wheel.

About Polishing Wax

The abrasive in the polishing wax will generate heat due to high-speed friction of the workpiece surface. Although the abrasive itself will have the ability to cut the material, however, because the abrasives from the oil soil are too fine to have the grinding effect. It is better to see it as a tool to create frictional heat.

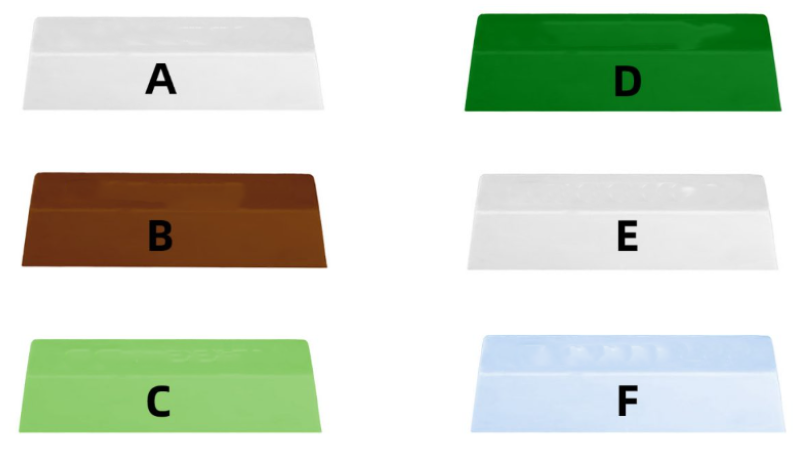

In China, we recommend to buy a series of polishing waxes from Makeraze which is relatively easy to find in large hardware stores if you have no idea. From “Rough to Fine” in the image below, it is ABCDEF, we recommend to buy ADF or ACDE. The matching of polishing wax and cloth wheel is the same as that of general polishing process: Rough polishing wax with heavy force, fine polishing was with light force, and the hardness of polishing wheels is matching with the roughness of polishing wax.

In addition, for reference, according to our actual using experience, the mesh of the A white bar shown in the below image is about 3000#, the D green bar is about 6000#, the F blue bar is about 12000#, you can see it as a reference when matching with other forms of polishing tools.

Although a abrasive in the polishing wax has a specific roughness, while since the effect of a polishing wax can vary over a wide range, we do not mark the roughness of polishing wax. So, the most accurate way to know the roughness is to actually use it, the heavier cutting force, the rougher polishing wax will be.

Under the premise of not spent money, the following methods that are only for reference for knowing roughness for polishing wax is:

1. The bigger bar, the rougher oil soil, because the rougher the larger the usage among all polishing consumables.

2. The higher price, the finer polishing wax, because the finer abrasive material the higher production cost.

Polishing wax of different roughness with the same brand will be distinguished by different colors. But don’t consider the same color oil soil of same roughness because there is not only one brand all over the world, and there is no global unified standard for the color and roughness of polishing wax.

Even though we differentiate roughness of polishing waxes by color, we can see two different color polishing waxes with same roughness in one brand from the above picture. We used to call them by green soil, green bar/white soil, white bar, it’s actually a mess.

Advice for Beginners: If for soft metal: Rough polishing (denim fabric or flat cloth wheel with B Tripoli bar )→ Middle Polishing(Stitched flat cloth wheel with D Green bar) → Fine Polishing(Non-stitched flat cloth wheel with C-26P)

If for hard metal, add a polishing process(Sisal wheel with A White bar) before the above recommended process.

What roughness polishing cloth wheel should be matched with what roughness polishing wax is completely free, and the force on the workpiece rubs the cloth wheel can vary (with your hands) over a wide range. Just make adjust according to the cloth wheel polishing theory, that say “Friction heat, plastic deformation”, don’t have to find the “correct” match.

About People

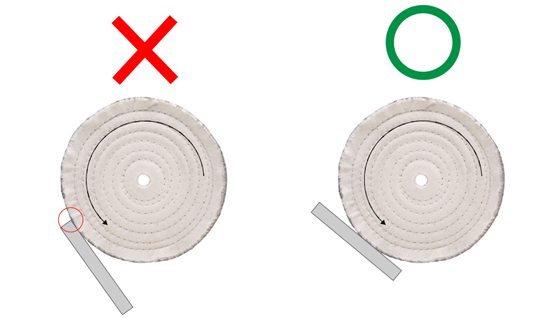

For safety, the most dangerous mistake a beginner will make is he/she will be thrown because polish the edge (corner and sharp edge) by cloth wheel, which will damage the workpiece at light and cause casualties at worst.

Once the edge of one side of the workpiece touches the cloth wheel, the cloth wheel will generate an impact force and act on the side of the workpiece to form a force of impact and twisting, which is same as a baseball pitching machine, so it is extremely dangerous.

Also, insulated gloves may be required because of the friction heat. Silicone insulated gloves are the best valuable; disadvantage is that it is very loose and does not fit tightly because it mainly used for baking.

Professional polishing factories usually have a set of large dust removal equipment similar to the layout of central air conditioning, connected to each work area via air hoses. Correspondingly, there is no such configuration for amateur occasions, so it is necessary to find a full set of protective equipment to protect yourself, try to wrap all exposed skin areas as much as possible, especially the face.

CAUTION! The main ingredient of polishing wax is wax, not tallow; it is completely useless to remove by general detergents, soaps, etc. It only can remove by some solvent, like degreaser. Our company has a variety of degreasers to choose, and we will write another article about it.

Practical Operating Modes and Principles

In general, we use cloth wheel to stick(polish) polishing wax to rub the surface of workpiece, keep the surface under observation which have not enough polishing wax, polishing two or three times by intermittent until the surface turn to smooth mirror surface.

It is should be noted that the process of cloth wheel polishing to create a smooth mirror surface is different to traditional polishing. Traditional polishing is a process from rough to fine by gradually changing the material surface from rough to smooth even to a mirror surface. The cloth wheel polishing changes the surface of the workpiece into a mirror surface at the beginning rough polishing process, the following processes are going to change the obvious polishing marks produced by the roughest polishing wax into unobvious polishing marks until satisfied.

If you are a beginner without any concept or going to polish a material has never seen before, you can try to do the following experiment: Put the hardest polishing wheel you have on the polishing machine, stick the roughest polishing wax you have, then rub the workpiece hard against the polishing wheel until the motor stop and relay off. Look into how much the plastic deformation of the workpiece, this is what you currently have can do the most polishing power. Many workers even use their knees to polish on the YouTube.

If there is not enough plastic deformation occurred, you can choose:

1.Change to a higher power polishing machine.

2.Look for a harder polishing wheel.

3.Look for a rougher polishing wax.

4.Give up.

Abrasive in oil soil have cutting ability as general grinding tools, also can do plastic deformation on the material through frictional heat. It is prefer to obtain mirror surface by plastic deformation if circumstances allow.

Cloth Wheel Polishing become a common grinding and polishing method if you cannot obtain a mirror surface by plastic deformation in some cases.

For example, the relay off before have enough plastic deformation because of the motor power of polishing machine too low, in this time, we can only use the cloth wheel as a common grinding tool to polish by light force. It is barely make plastic deformation on the black iron tube which is hard metal by a low power flat grinder shown in this case. Other example: as the following image, the workpiece is too fragile to rub on the polishing wheel; we can only polish it by very light force.

There is nothing wrong to see cloth wheel as a general grinding and polishing tool (no plastic deformation), but it is better to have plastic deformation if circumstances allow since this is the strength of cloth wheel polishing and the soonest way to get perfect mirror surface.