This article is also available in the following languages:

Tiếng Việt

繁體中文

Over Polishing

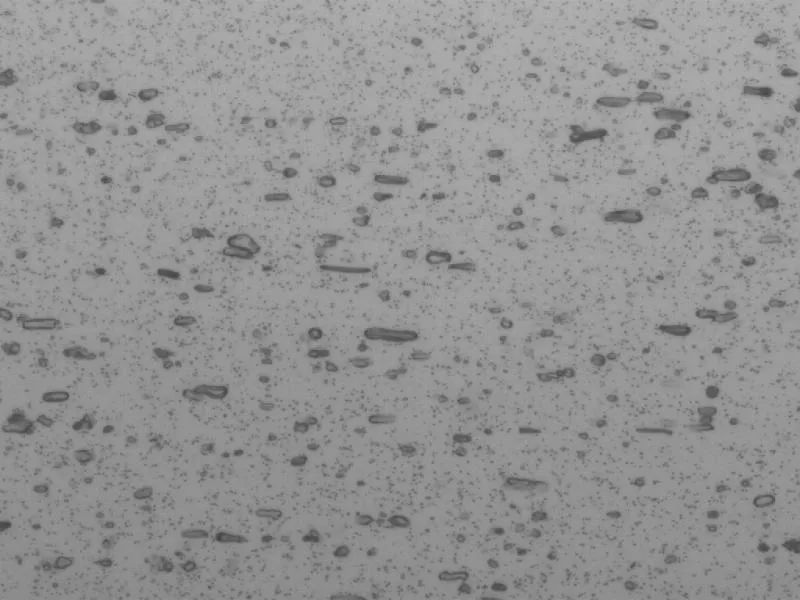

A problem encountered often in daily polishing process is “over polishing” what means worse mold surface by polishing time too long. There are two types of over-polishing: “orange peel” and “pitting”, mostly occurs in mechanical polishing.

Why “orange peel” appears?

We call irregular rough surfaces as “orange peels” and there are many causes of it.

The most common reason is the mold surface or excessive carburization overheat, excessive polishing pressure and too long polishing time are the main reasons for “orange peel”.

How to remove “orange peel”?

When it is found that the polishing surface quality is not good, many people would like to increase the polishing pressure and extend the polishing time, which tends to make the surface quality get worse.

We recommend the following polishing methods:

1)Remove “orange peel” surfaces. Using grit size is one grade coarser and lower force than previously used to polish.

2)Stress relief at below tempering temperature 25°C, using the finest mesh to wipe until get satisfied effect before polishing, and then polishing by a lighter force.

Why “pitting” appears?

Due to some non-metallic impurities in the steel, usually hard and brittle oxides, they are pulled from the surface of steel during the polishing process, forming craters or pitting corrosion.

The main factors that cause “pitting” are as follows:

1)Polishing pressure too much and polishing time too long.

2)Steel purity is not enough, and the content of hard impurities is high.

3)Rust on the mold surface.

4)Do not remove the non-clean up places.

How to remove “pitting”?

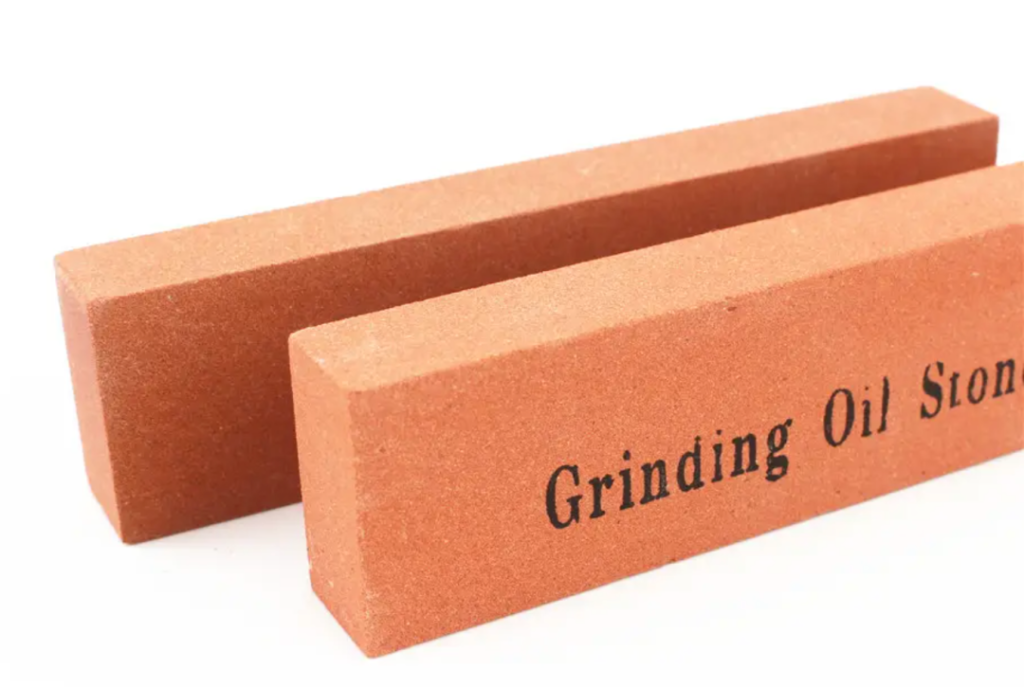

1)Using the grit size is one grade coarser than previously used to regrind the surface carefully; Using soft and sharp oilstone for the final step of grinding before proceeding with the polishing process.

2)Do not use the softest polishing tool when the grit size is less than 1 mm.

3)Use the shortest polishing time and minimum polishing force as much as possible.

Cavity polishing is a very important process in mold production; it decided the quality and life of molds, also the quality of molded product.

Mastering the working principle and process of polishing, choosing a reasonable polishing method, can improve the quality and life of the mold, thereby improving the quality of molded product.