This article is also available in the following languages:

繁體中文

When we look at a piano, we usually notice its appearance first, and sometimes we are also curious about what kind of “hardening” has the blunt wooden board gone through to have such an exquisite and beautiful finish as the piano shell?

Common piano finishes include high-gloss (high-polished) finishes, satin finishes, and open finishes often seen on European pianos. The satin finish reflects light but doesn’t reflect the image. The open finish is mainly used on pianos with a cabinet with a natural wood finish. The high-gloss finish is almost like a mirror, reflecting both light and image.

Today we focus on introducing how the high-gloss finish of the piano is formed.

Baked lacquered surface treatment of piano shell

If you want to make the piano shell into a high-gloss finish, you must lacquer the piano at first. The piano baking lacquer process is a kind of baking lacquer process. Its process is kind of complicated. First, putty needs to be applied to the wood board as the bottom layer of the spray paint. When the putty is leveled and dried, we can start to polish it until its surface become smooth; then sprayed repeatedly 3 -5 times of primer. After each spray, polish with water sandpaper, and abrasive cloth. At last, spray 1-3 times of bright topcoat, and then use high-temperature baking to cure the lacquer layer.

The piano’s baked lacquered surface is characterized by bright colors, and colors can be freely adjusted according to customer requirements.

Baked lacquered surface polish treatment of piano shell

Paint the piano shell’s surface with lacquer and bake it at high temperature is only the first step to make a piano shell into a high-gloss finish.

For pianos with different lacquered surfaces, different polishing schemes need to be customized.

Jiangmen Makeraze Technology Co., Ltd. uses the century-old Makeraze brand technology in polishing and other surface treatment technologies. We provide customers with various surface treatment solutions and high-performance materials for a long time. The following is the polishing solution provided by Jiangmen Makeraze Technology Co., Ltd. for common piano-baked lacquered surfaces: The polishing materials required in the polishing process can directly use Makeraze products.

Option 1: Sanding → Rough polishing → Fine polishing → Light receiving

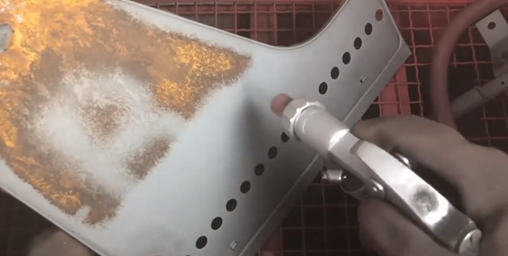

1.Sanding: After painting the piano shell with lacquer and baking it, the paint surface may have impurity blisters and the surface is corrugated and uneven. Use #400-#600-#800 sandpaper to sand in order to remove impurity blisters on the paint surface. And smooth the surface.

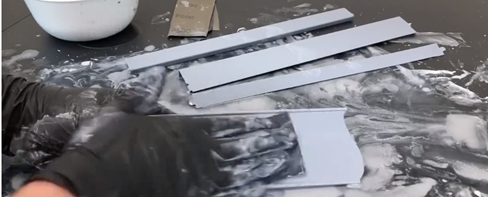

2.Rough polishing: The main purpose of rough polishing is to treat the remaining polished traces of the surface treatment and improve the surface smoothness and gloss. The polishing material can choose the Bias Cut Cloth Buffs and white polishing compounds SBW-801 for polishing. After rough polishing, the gloss of the paint surface can reach 90~92Gs.

3.Fine polishing: the fine polishing process is progressive from the rough polishing process, and the main purpose is to deal with the traces remaining in the rough polishing process and further improve the surface smoothness and gloss. The polishing material can be polished with Bias Cut Cloth Buffs and fine polishing white compounds SBW-825A (all specifications of polishing compounds are precisely adjusted for the industry, and samples are welcome). After fine polishing, the gloss can reach 93~94Gs.

4.Light receiving: Receiving light is the key to forming a high-gloss finish. You can choose the yellow Woolen Wheels 3M05705 and Makeraze lacquer mirror finishing water wax V-39 for the final refinement process, and finally form the mirror effect of the piano high gloss finish.

Option 2: Dry grinding→Water grinding→ Light receiving

1.Dry grinding: Use #600 and #800 dry grinding pads to dry the piano lacquer in turn.

2.Water grinding: After dry grinding, use #1200, #1500, #2000 water grinding pads to polish the paint surface.

3. Light receiving: Use yellow Woolen Wheels Woolen Wheels 3M05705 with lacquer mirror finishing water wax V-39 for the final refinement, and finally form the mirror effect of piano high-gloss finish.

After the above-mentioned surface treatment, the piano’s exquisite and beautiful high-gloss finish is formed.

The above pictures are from the Internet.