1.png)

This article is also available in the following languages:

繁體中文

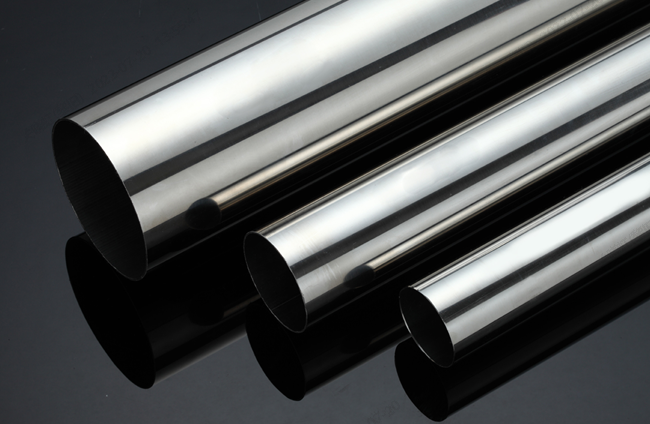

Stainless Steel Round Tube

With the continuous improvement of material and cultural standards, the demand for stainless steel pipes (including stainless steel composited pipes) is increasing, higher requirements are placed on polishing of stainless steel pipes. Thus, stainless steel pipe polishing line (stainless steel pipe polishing machine) came into being.

The round tube polishing machine works mainly relies on three parts: material feeding, motor speed regulating and polishing machine, simultaneously convey raw materials. Polishing machine consists of six sets of polishing heads, each of which is driven by a three-phase motor.

Using emery cloth and grinding wheel for rough and semi-fine, fine polishing of stainless steel pipes(The surface roughness RA value can be reached to 0.1~0.05μm by using PVA grinding wheel for fine polishing ) Polishing by a single grinding head which suitable for PVA grinding wheel also emery cloth and grinding wheel with mesh180# for small diameter stainless steel pipes.

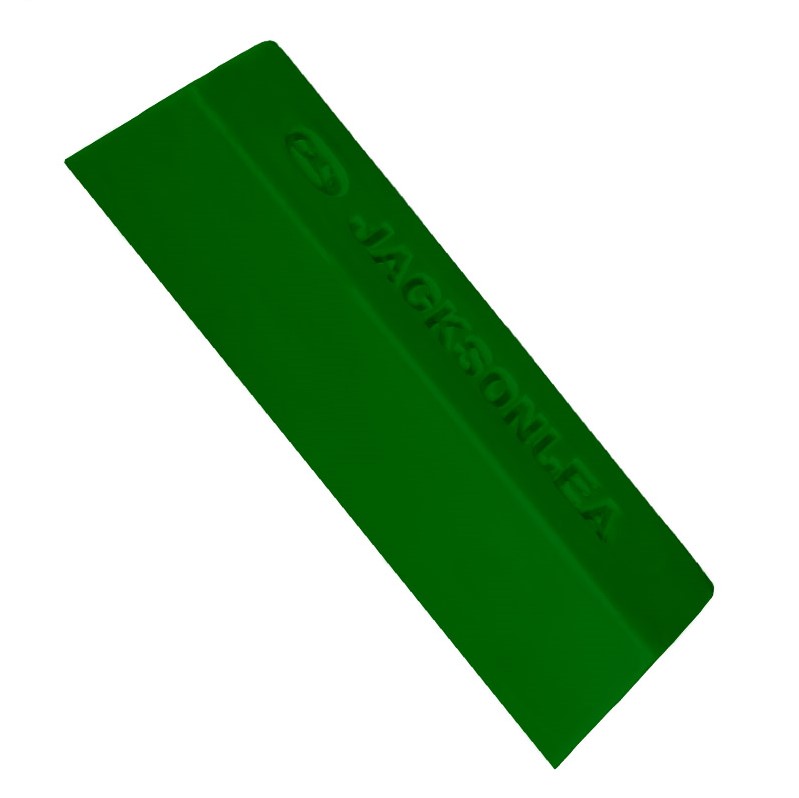

Stainless Steel Rectangular Tube

Stainless steel rectangular tube polishing machine consists of feeding, polishing host and cutting. The polishing host with four sets of plane polishing mechanisms and four sets of side polishing mechanisms is driven by a speed regulating motor to realize the feeding and conveying of raw materials.

Using emery cloth wheel for rough polishing of stainless steel pipes, green polishing compound and cloth wheel for fine polishing using(The surface roughness RA value can be reached to 0.1μm after finished).

In polishing for round and rectangular stainless steel tubes, some small companies also use simple single head polishing machine by changing wheels and repeat operating time after time to meet requirements.

The above pictures are from the Internet.