This article is also available in the following languages:

Tiếng Việt

繁體中文

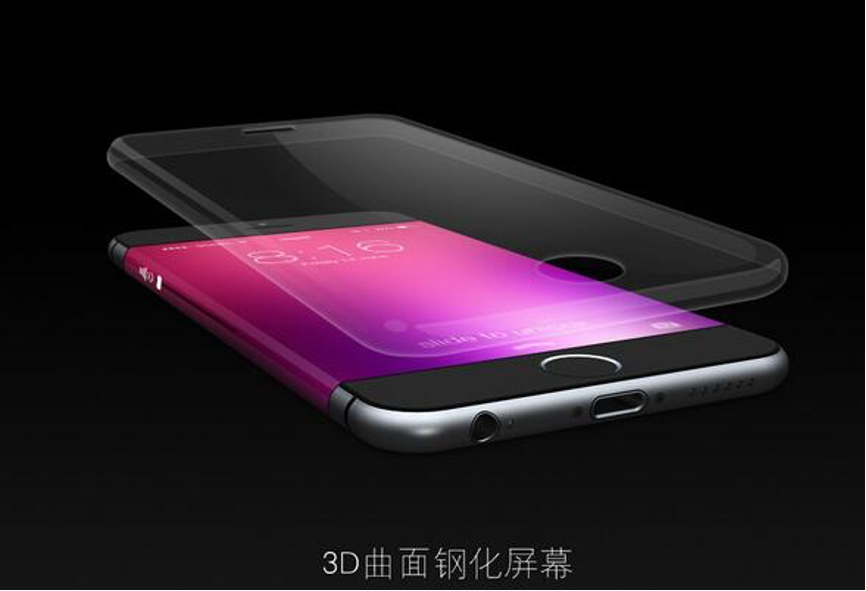

Now the development of mobile phones has progressed to mobile phone surface screen, the screen glass and cover on the phone also with the shape of the phone, the introduction of a variety of 3D surface glass and surface cover.

Previously, most phones used a 2.5D screen also known as a “water drop screen”,2.5D surface screen and 3D surface screen is different from the screen arc,2.5D only on the edge of the screen to do radian processing,so that it looks like water covered the screen without overflowing so called “water drop screen.” Compared to the 2.5D screen, 3D surface glass not only has an arc at the edge of the screen, but also allows the entire screen to have an arc, and has anti-fingerprint, anti-glare, scratch-resistant and other characteristics, and compared to the 2.5D surface screen looks more beautiful.

But all smooth-looking glass needs to be “polished” to achieve a transparent and clean effect, and the entire plane of 3D curved glass is curved, which is not possible with traditional polishing techniques. At present, most of the industry uses flat polishing machine to throw 2.5D cover glass, good yield in 70% to 80% of the single process. The polishing time(12-15 minutes) varies depending on the slope size,and the CNC program has different polishing lengths. 3D glass polishing is not only a new polishing solution, but also a new attempt, 3D glass polishing is still in a trial stage, not yet to withstand the popularity stage, so 3D glass polishing will be another new direction and new trend in the industry.

3D glass polishing is one of the four major difficulties in the process. 3D processing, generally need to go through two polishing, one is before the hot bend, after the polishing, the other is after the hot bend polishing.

At present, most of the industry uses flat polishing machine to throw 2.5D cover glass, good yield in 70% to 80% of the single process. The polishing time (12-15 minutes) varies depending on the size of the bevel,and the CNC program has different polishing lengths.

Today, most mobile phones in order to improve mobile phone security, have mobile phone fingerprint recognition, and for fingerprint cover polishing yield is lower, take longer mostly in 45-70 minutes, cut yield has not been about 50%-60%, resulting in very large use of consumables.

So 3D glass polishing is not only a new trend but also a new difficulty in polishing.