White Bar Compounds

- Provides high-quality gloss.

- It has a certain cutting power and good gloss.

- With strong cutting power, the surface of the polished parts can be very uniform and well gloss.

- Aggressive cutting ability on ferrous and non-ferrous metal, and work with cloth buffs or sisal buffs to get excellent heavy cutting.

- With a certain cutting power, to eliminate the sanding line of grit #600 or #800, and well gloss. The cutting power is stronger than SBW-801.

This article is also available in the following languages:

English

繁體中文

White Bar Compounds

Product Parameter

| Attributes | Parameters |

|---|---|

| Product name | White rouge Polishing Compound / Lacquer Hi-Gloss Bar Compound |

| Another name | Buffing compound, bar compound, white polishing compound |

| Specifications | SBW-801 / SBW-801H / SBW-801AY / SBW-804 / SBW-804H / SBA-77 / SBA-703F / SBA-705 |

| Product material (Abrasive) | High quality calcined alumina / High quality micron calcined alumina |

| Appearance color | White |

| Water-based/Solvent-based | Solvent-based |

| Product volume | 525.5cm³/Bar |

Applicable industries

Musical instrument industry

Hardware industry

Furniture industry

Bathroom industry

Polishing workpiece type

Acrylic surface

Plastic surface

Aluminum surface

Stainless steel surface

Process treatment

High quality calcined alumina

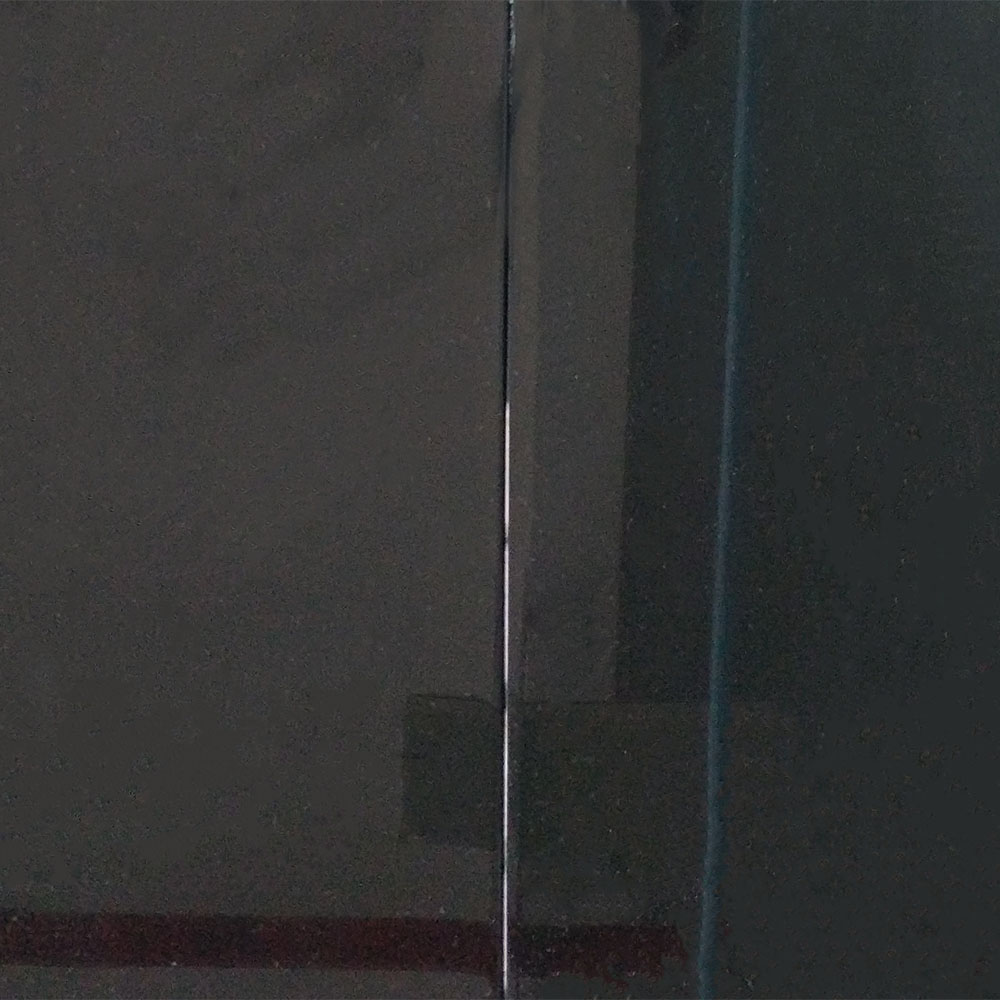

Before and after comparison

Our Company

MAKERAZE, Located in the high-tech industrial zone of Jiangmen, Guangdong Province, China. We have the professional production technology of buffing and polishing materials in the surface finishing industry for about 100 years.

The industry which we serve is included in Automotive Aluminum Wheels、Door Hardware、Cutlery、Automotive Dashboard、Plumbing Fixtures、Cookware、Lighting、Fireplace Hardware、Medical and Dental、Printed Circuit Boards、Cell Phone Case、Lock Hardware、Musical Instruments、Furniture、Jewelry、Medical equipment…

The products which we supply are including Buffing Bar Compounds、Buffing Liquid Compounds and Spray Gun System、Cloth Buffs、Sisal Buffs、Pressure Tanks、 Buffing Equipment、Grinding Materials、Specialty Abrasives、Non-woven and Coated Abrasive Rolls、Flap Disk、Flap Wheels、Belts and Convolute Wheels、Fuel additives、Buffing Raw Materials、Polishing Materials.

We have a raw material laboratory with R&D ability to give us the well-skilled to adjust the formula of buffing compounds. Regarding the finished products, which are tested by a robotic cell in our appliance laboratory, give us the highest performance by simulated and alternative testing, meanwhile, it gives the best production benefits to the customers. We also support OEM which is required by various brands. And sincerely welcome to have any joint of cooperation and any inquiry.