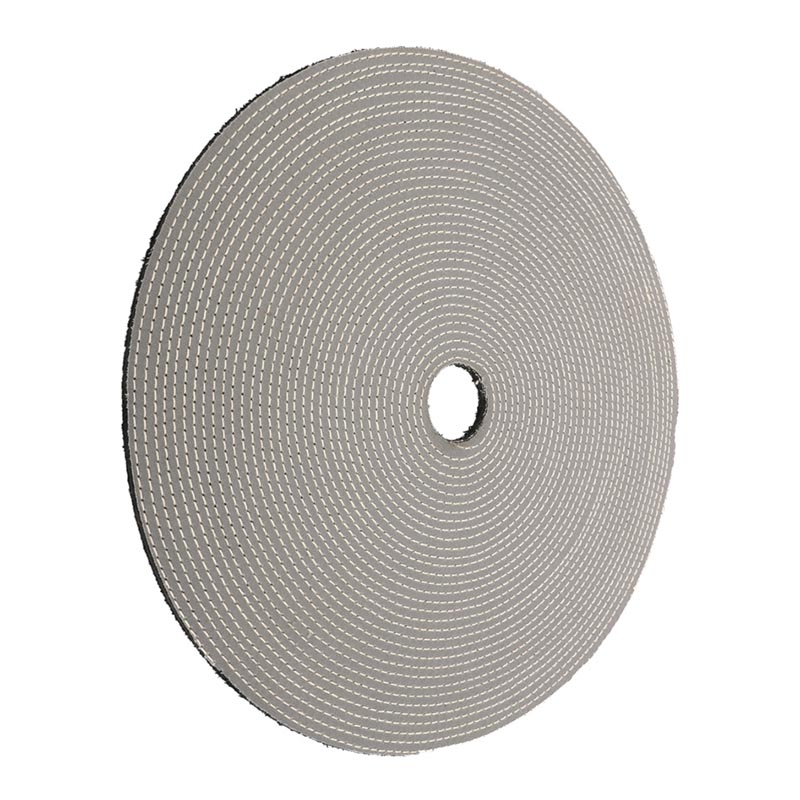

Bias Cut Cloth Buffs Riveted

(1) The cutting power of buff is enhanced after solvent base chemical treatment, which can reduce the polishing time by 20%.

(2) After chemical treatment, the life-lasting is more than 40% longer than the general untreated buff.

(3) Excellent absorption by the bar and liquid compounds, which can save more than 30% of the compound consumption.

(4) Irregular packed, which exerts a self-cooling effect during the polishing process.

This article is also available in the following languages:

English

繁體中文

Bias Cut Cloth Buffs Riveted

Product Specifications

| Attributes | Parameters |

|---|---|

| Product Name | Bias Cut Cloth Buffs Riveted |

| Other Name | Riveted Airway Buffs |

| Product Specification | Outside diameter: 8″-12″ Inside diameter: 19mm, 25mm, 40mm Number of layers: 32P-72P Packed: #2-#6 |

| Product Material | Solvent base treated cloth |

| Appearance Color | Black Dark Blue Orange Red Gold |

| Applicable Washer Diameter | Customizable |

| Maximum Speed | 2200RPM |

| Thickness | 15~60mm |

| Hole Diameter | 19mm, 25mm, 40mm |

| Hardness | Hard |

Applicable Industries

Hardware Industry

Lock Industry

Kitchenware Industry

Bathroom Industry

Electronics Industry

Applicable Material

All kinds of metals.

Plastic

Save durable

The life-lasting is more than 40% longer than the general untreated buff.

CCan save more than 30% of the compound consumption.

Facing Service (Paid service)

The surface of the cloth wheel is raked and facing, the part is evenly contacted during polishing. The facing surface of the cloth wheel is easier to absorb the polishing compounds to quickly achieve run-in production. For the initial polishing, it will be more delicate, quality consistency, and anti-scratch on parts.

Process Treatment

The bias cut cloth is formed into a clinch ring by”J” machines, then riveted with cardboard and high-density fiberboard after treating by solvent base chemical treatment.